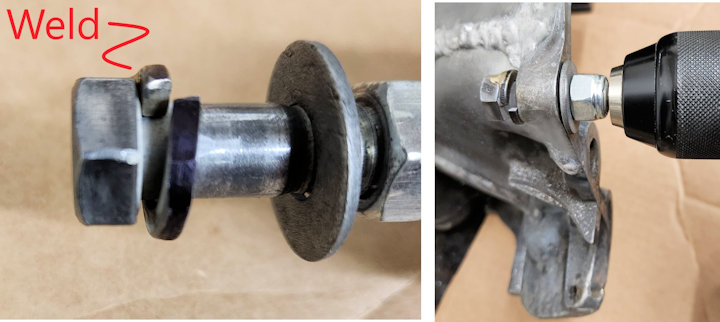

An aluminum transmission’s mounting bolt hole needed to be spot faced after a TIG welding repair. The situation called for a Back Spot Face Cutter, however the size cutter needed was not available. To make a cutter, I turned a short section of threads off the end of a 7/16 hex bolt (which was a snug fit in the transmission’s hole). This allowed it to be chucked in a cordless drill. Next, I used a Dremel tool to sharpen the existing corner edges on one end of a 7/16 lock washer. I brazed the washer to the hex bolt, making sure the cutting edge faced the correct direction when the drill spun clockwise. To use the tool, install it with a flat washer and Ny-lock nut to limit the depth of cut per “pass”. Once the weld was spot faced even with the unwelded area, pulling out on the drill/tool made a nice smooth finish “pass”. On this nasty cast aluminum, it cut easily. However, if and when the cutter dulls, re-sharpen the lock washer end edges with the Dremel. Quick and “dirty” but works great.

Tom Nichols

Automotive Machine & Supply, Inc

Cleburne, TX