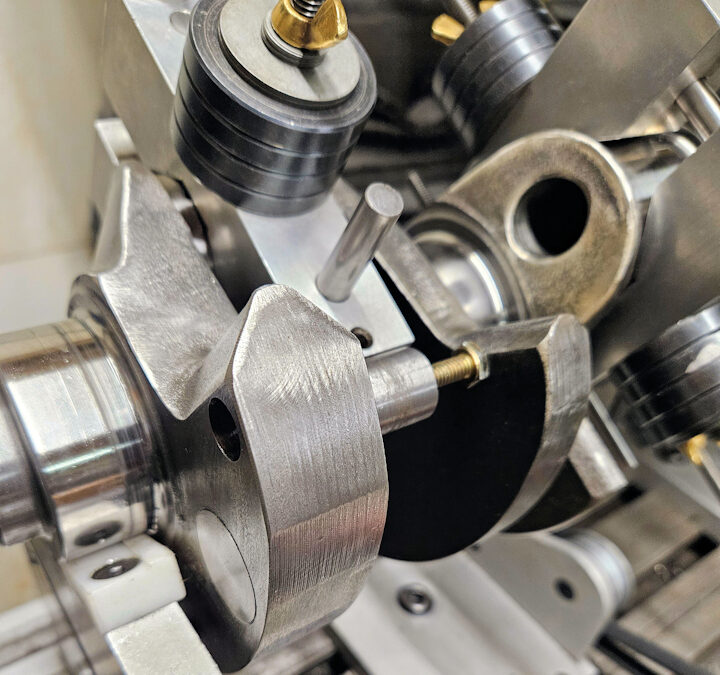

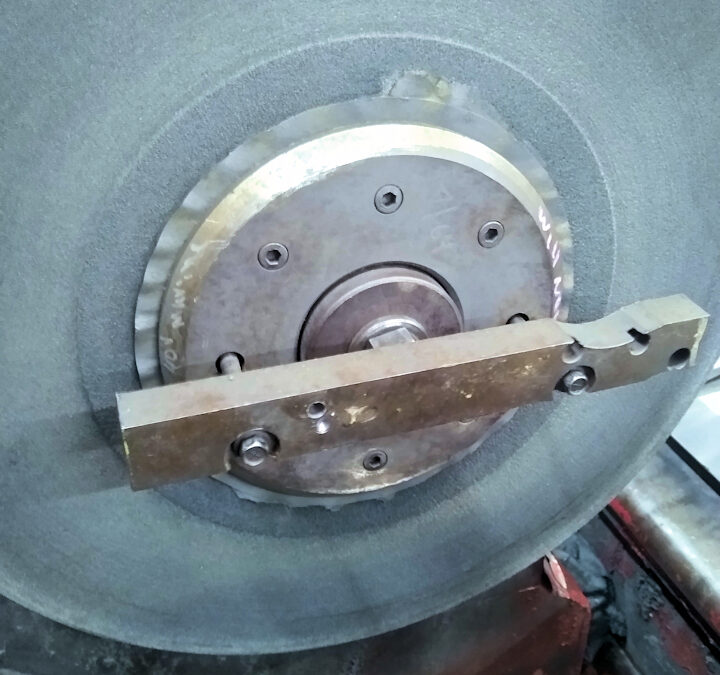

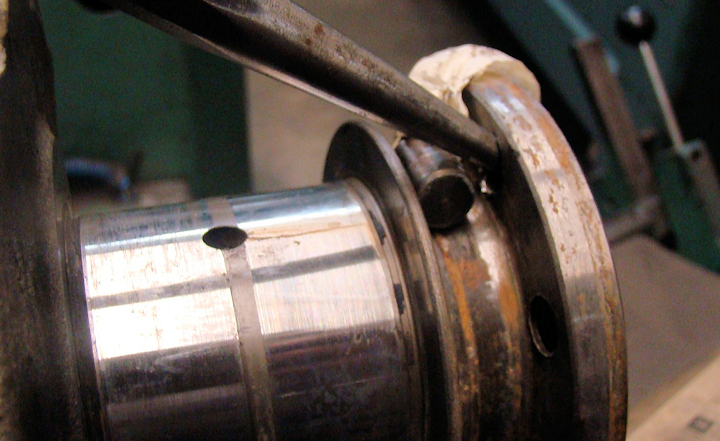

Sometimes it's nice to be able to test what effect adding weight will have to a crankshaft balance. Since modern balancers also read cross planes, the placement can sometimes get tricky. This is especially true if the opposite side is close to the edge of the...