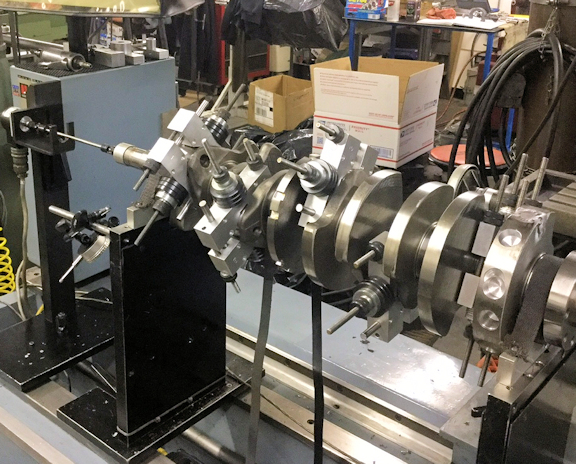

RELUCTOR WHEEL INSTALLATION TOOL We made our own reluctor wheel installation tool for LS engines, and it works like a charm. We used junk materials from around the shop, including an old valve stem, and have about 2 hours of labor into making it. A chunk of 1/2" plate...