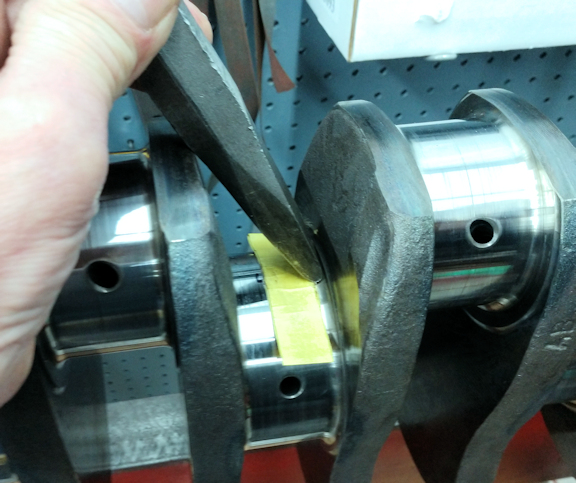

TWICE THE SCALE I adapted this rod weighing setup after seeing my friend doing something very similar. If the point of contact with the scale is not the dead center of the bore on each end of the rod, you will not get accurate readings. I turned some mandrels on the...