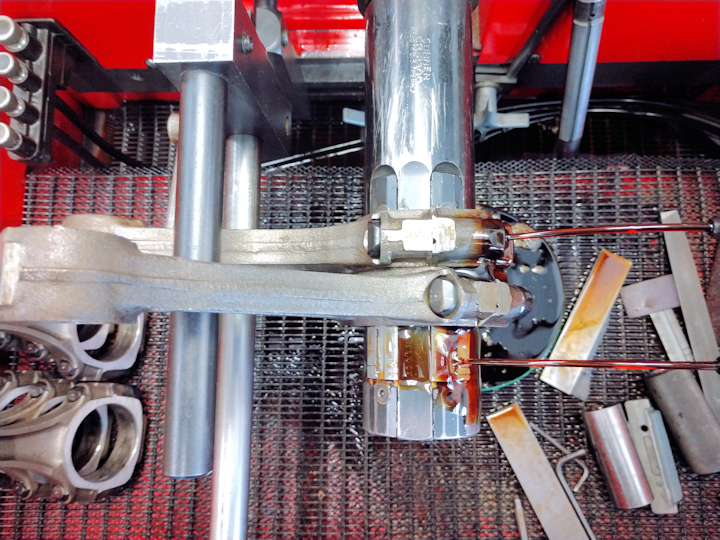

LS CRANK I.D. The 5.3l and 6.0l LS engines use the same stroke crankshaft with the same casting number. But the balance is different on the cranks for the different bore size pistons. There is a quick way to determine which crank you have. If you look at the front and...