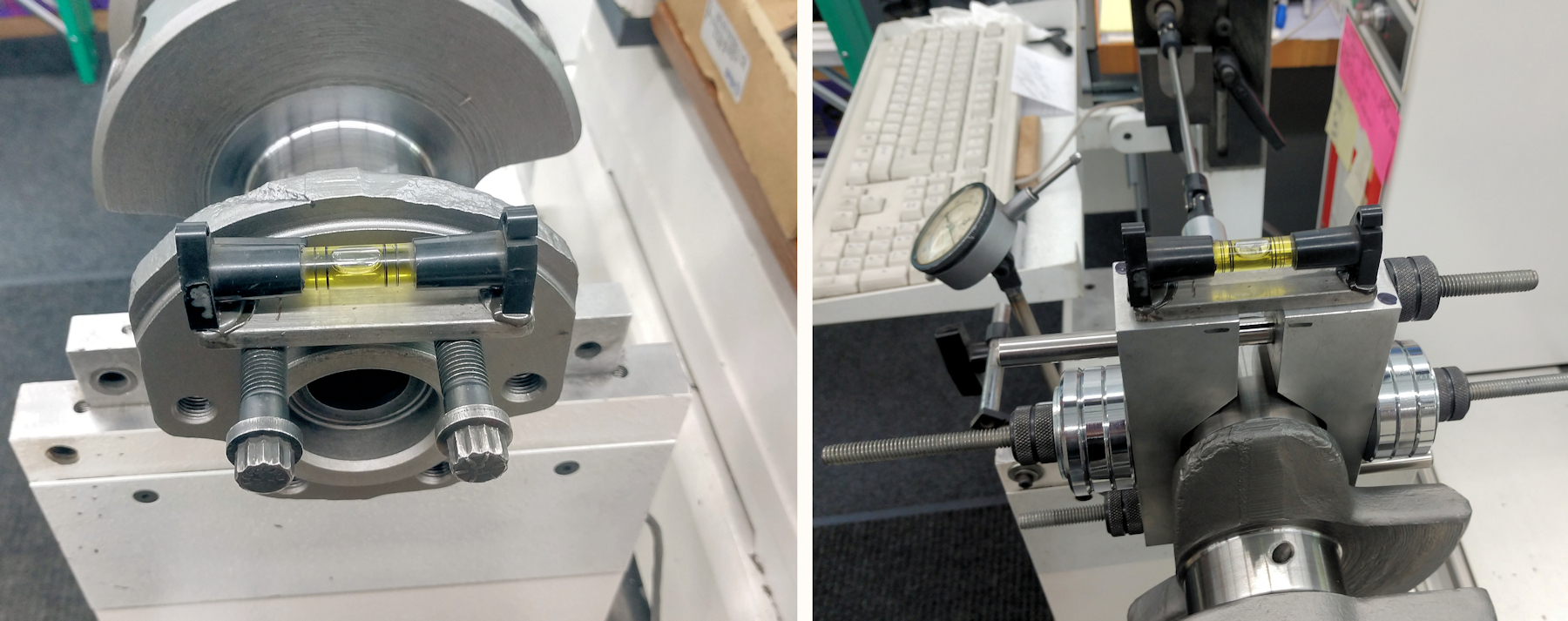

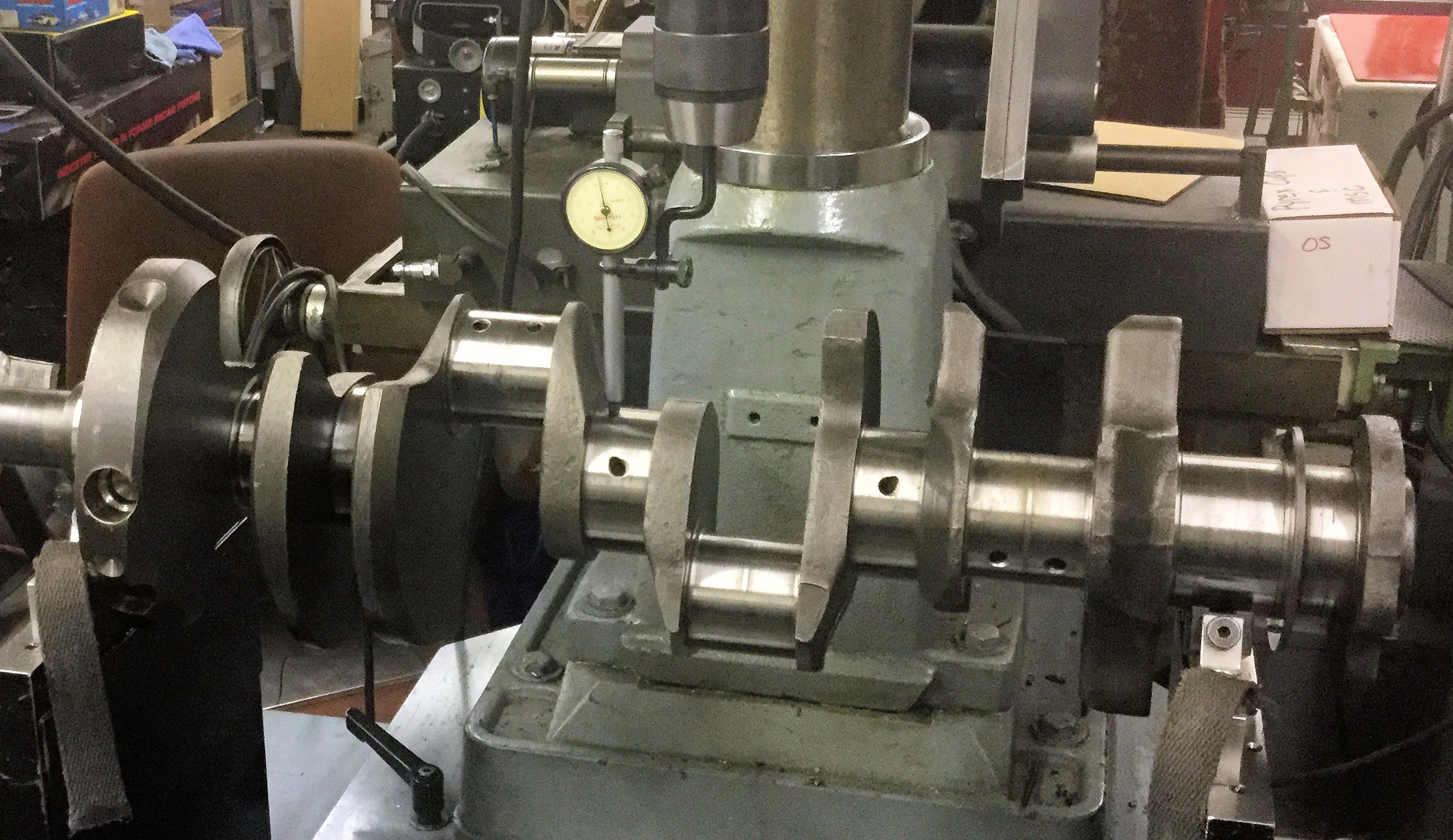

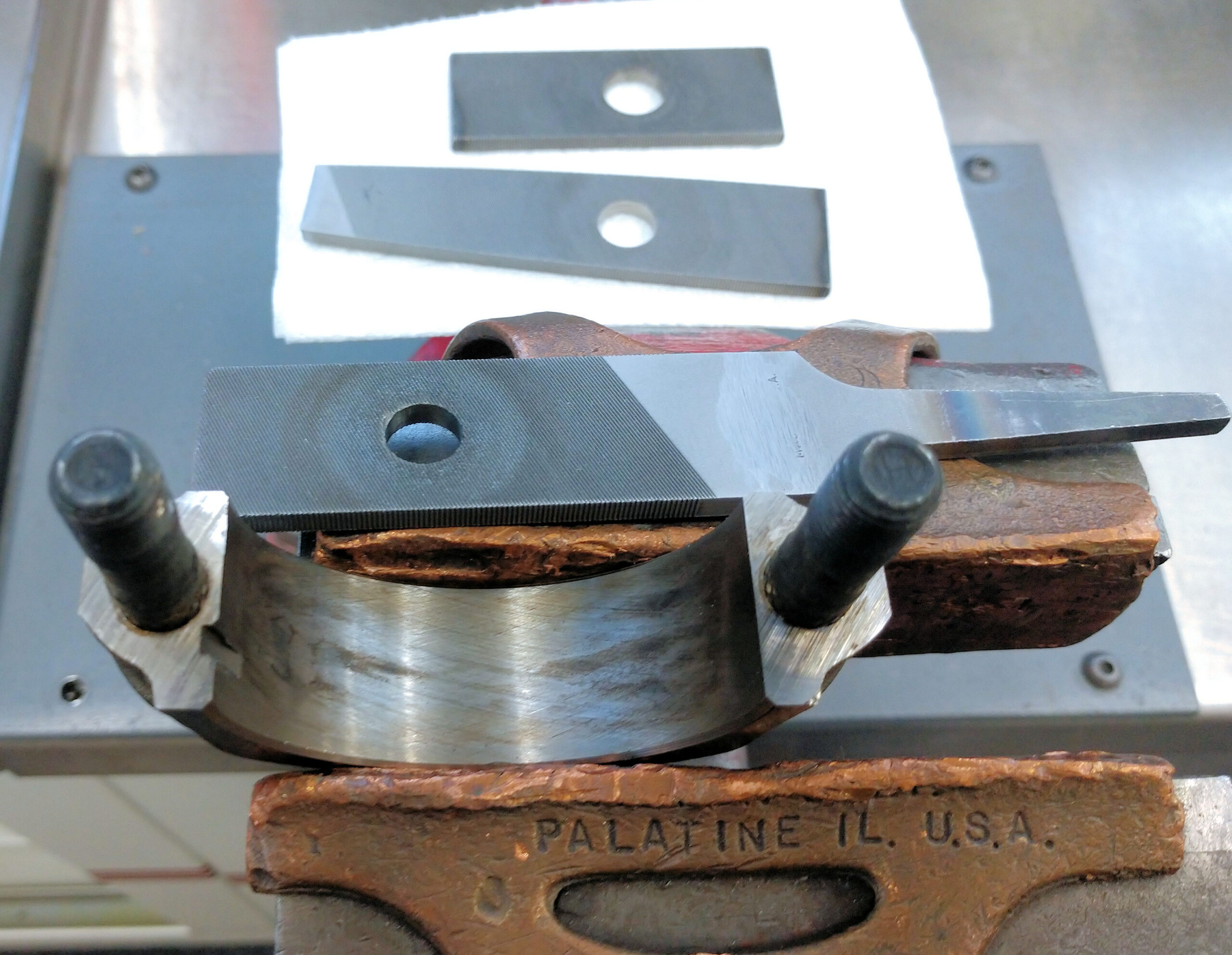

BOBWEIGHT PLACEMENT I always “phase” my bobweights. I start by screwing in a couple bolts into the crankshaft flange. It seems to be a good starting place and seems to place the first throw up. I level across the bolts then 0 my degree wheel. Then I level each...