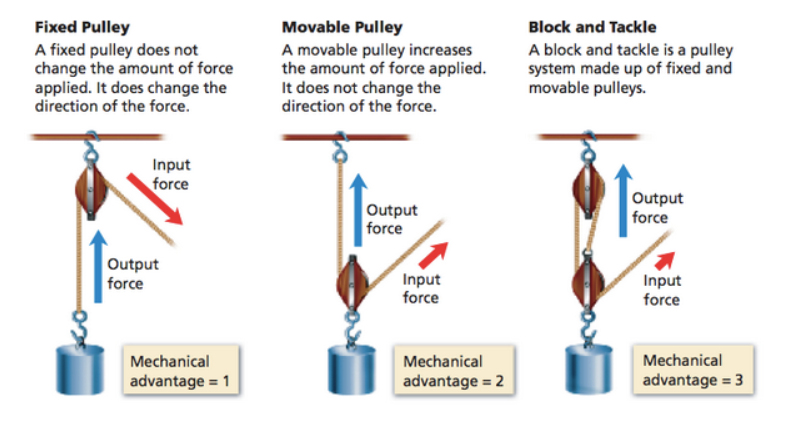

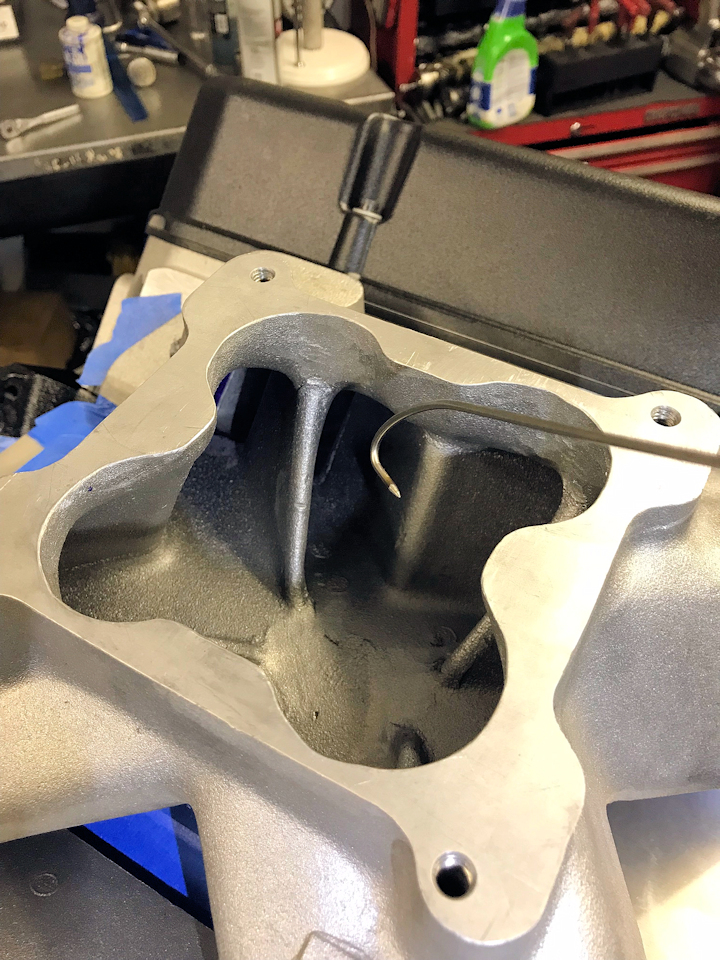

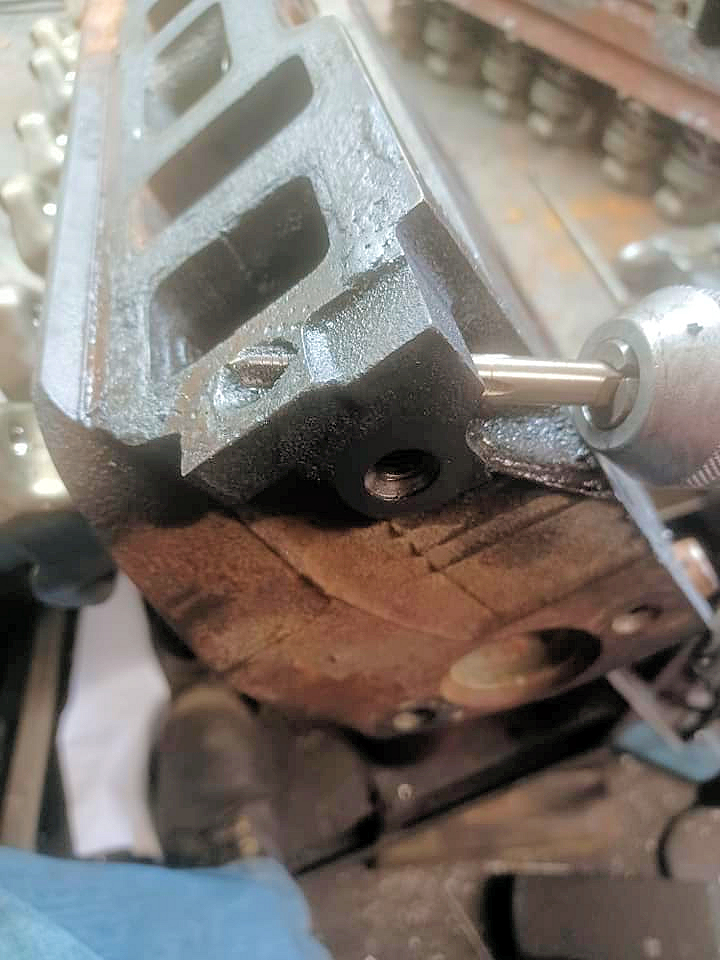

DOUBLE YOUR STRENGTH Lifting heavy objects is an everyday occurrence in machine shops. To prevent injury, it’s a good idea to install small, inexpensive wire cable hoists over equipment that can hold castings in place while mounting to machinery. Small hoists that...