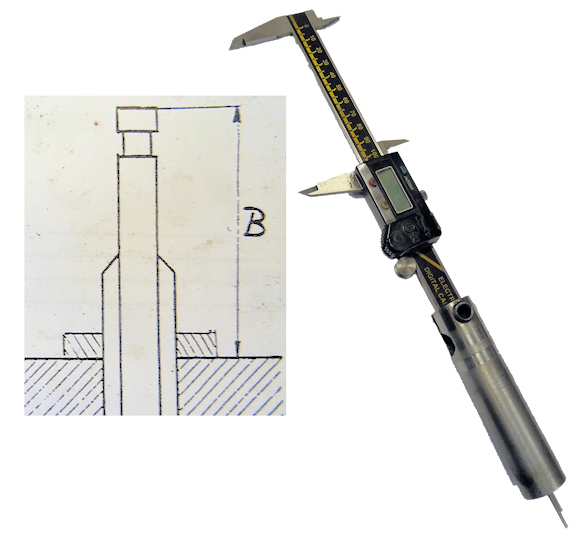

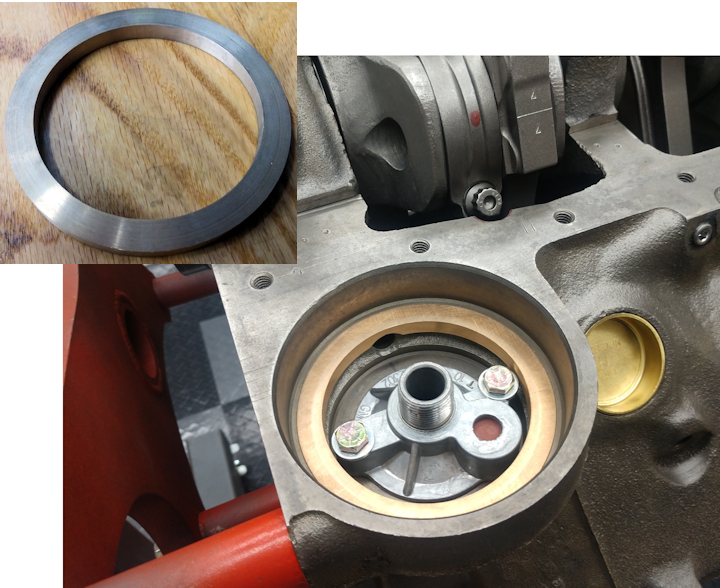

O’RING END STOP When honing some parts on the rod machine, I use an O-ring on the mandrel as a visual end stop for proper overstroke. This really helps on things like motorcycle cases and multi rod assemblies to ensure proper mandrel over stroke coverage. It also...