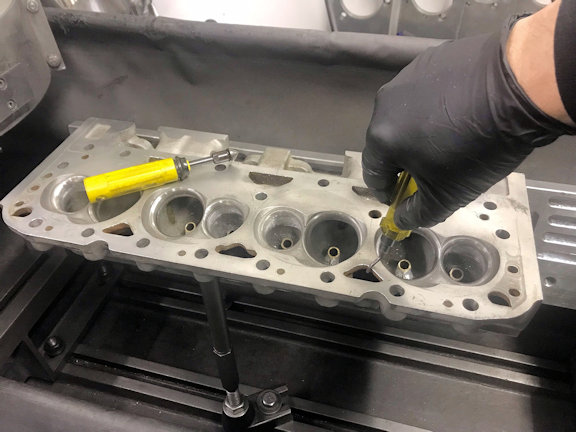

INSTALLATION TOOL TOOL When installing a reluctor wheel on an LS crankshaft, using the brand name alignment tool, use a piece of 4.5" pipe, notched and with a bar welded on the back to take the hammer blows. I can avoid banging on the tool and this provides a better...