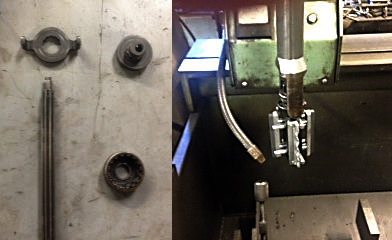

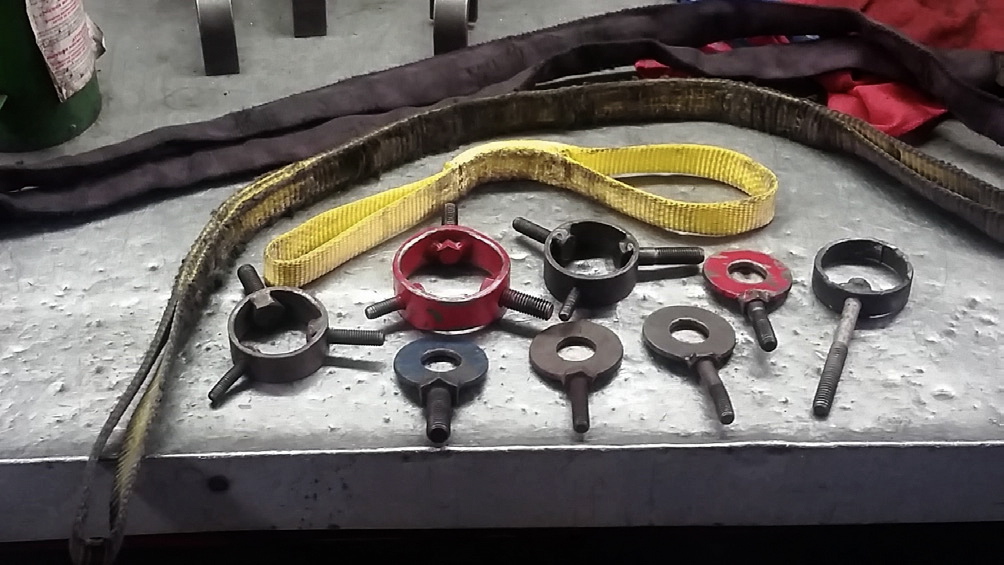

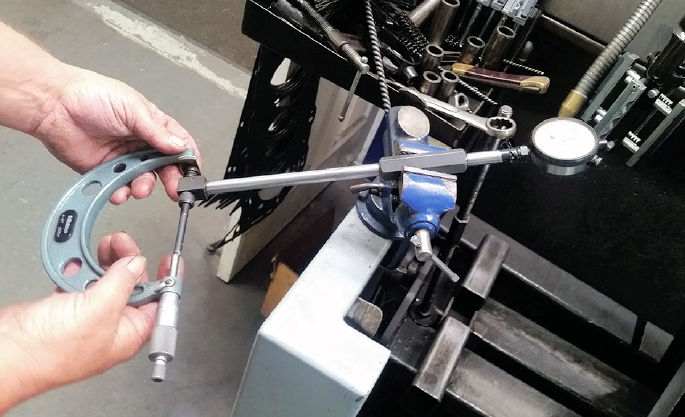

ROTTLER HM3 HONE REPAIR Here is how you can repair the Hone head since Rottler does not service the head any longer. You can use a Regis part number RSI218. You will need to drill out the top of pinion to remove the expander nut. Then cut the top of the shaft and...