I use magnetic hooks around the shop to organize and hang small items. They do work great in the hone cabinet, and I don’t need to wash the gaskets every time. A pack of 20 hooks cost around $10. Randy Torvinen Torvinen’s Machine Menahga, MN

I use magnetic hooks around the shop to organize and hang small items. They do work great in the hone cabinet, and I don’t need to wash the gaskets every time. A pack of 20 hooks cost around $10. Randy Torvinen Torvinen’s Machine Menahga, MN

Since we’re always looking for new and better ways to machine, we often have to make tool holders and other items. Locating the raw material or turning down stock is always part of the process. I’ve found that valve stems often have the same size as much of the...

Sometimes we need to use a dial bore gauge that is set-up directly off of a micrometer. It can be hard to center both ends of the bore gauge with micrometer's anvils. Simply cut a small piece of 1/4" rubber tubing and slip it on one side. The bore gauge end will slide...

When working with different manufacturers of blocks, lifting bolt sizes can vary significantly. Our solution was to elongate the bolt holes of our lifting chain on the links towards the end, so that larger diameter bolts can slip through. We then have the thread size...

VOLTMETER SPEEDOMETER For those like me who possess a head and block surfacer that employs a potentiometer to adjust the speed of the traverse, I install a D.C voltmeter on the voltage input of the D.C drive motor. Now I adjust the finish by the voltage of the motor...

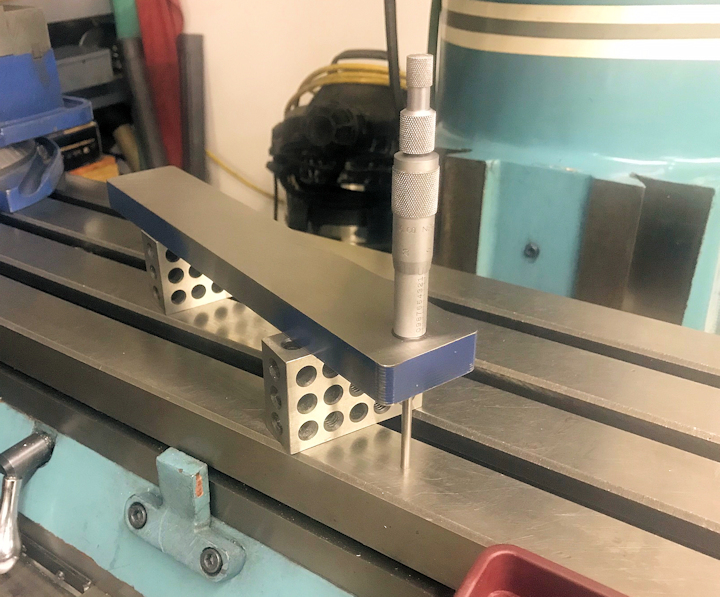

MIC CHECK, CHECK One often overlooked item for regular calibration is the common block deck mic and depth mics. Simply lay it on the corresponding precision blocks on your mill table, or known true surface, and check them once in a while. Ron Flood Cedar Machine North...