REMOVE THE WEB

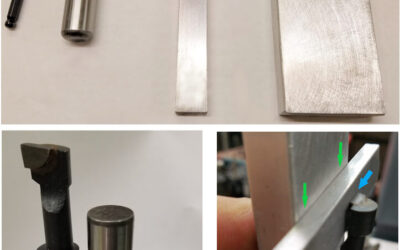

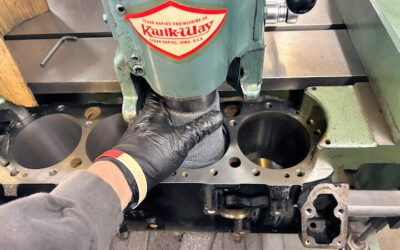

We have noticed through the years that many previously bored blocks come into our shop that have not had the web at the bottom of the cylinders relieved even with the bottom of the cylinders. Depending upon the bore’s oversize this can be a potential problem point for a quality build. When the web hangs below the bore two problems may occur. First, the web will bear against the hone head and push it to the side, leaving a bend or small hook in the bottom of the bore, away from the web, and a low spot at the TOP of where the stone stops at the bottom on the web side. The second problem is that this will usually chip the bottom of the stones. The chipped stones results in this cylinder and the later honed cylinders having a smaller bore/hone size at the bottom of the cylinder. We check every block before honing to catch this potential problem area. We have found that the easiest way to remove the web is use an extended/long die grinder with 2 or 3, 3” cut-off wheels mounted on an arbor to grind the web away. How to see down in the bore easier? The same place that you bought the cheap extended die grinder also gives you a free small LED flashlight with your purchase, so just tape it to the lower end of the die grinder and you have a very cheap, effective, and well lit web removing tool.

Timm Jurincie

TUF-ENUF Auto & Marine Performance

Avondale, AZ

September, 2014