GROWING ALUMINUM

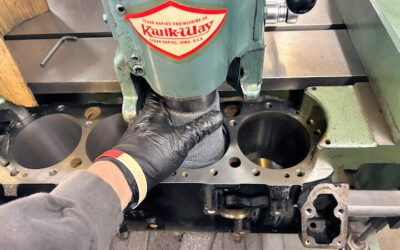

We live in a time where aluminum blocks with cast-in sleeves are common. We build several dozen Gen III and Gen IV GM LS type motors per year. We finish our cylinders .001” tighter on the aluminum block engines to compensate for the additional growth when the block gets up to operating temperature. This is easily tested. Check your cylinder diameter just before and right after removing from your jet washer. The difference between the aluminum and iron blocks is measurable, and this is only about 135 degrees. Much lower than engine operating temperature. Cam bearing interference can also be a problem on the aluminum blocks. We always use the new late model cam bearing set developed for the engines with variable cam timing. The diameter is approximately .0005” larger and the added width increases surface tension.

Tim Schwanke

Schwanke Engines LLC

Springfield, MN

June, 2016