1) Always file only one end of the ring: this will allow for a quality inspection of the ring after use to identify witness marks of “ring butting” from insufficient ring end gap

2) Always use a gauge pin to check the ring end gap instead of a feeler gauge. This will allow the ring to remain positioned without upsetting it, resulting in a more accurate measurement of the ring end gap. A feeler gauge will upset the ring’s position nearly every time. This method provides a more sensitive touch in knowing exactly where the ring end gap is tight or loose in a particular gap area.

Insufficient ring end gap is the cause of more than 95% of our piston, ring and cylinder failure or damage.

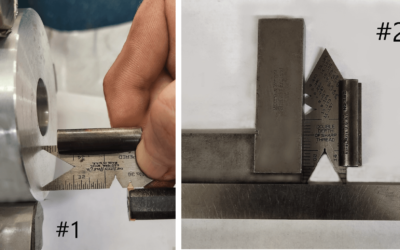

Note: The picture is of witness marks or ring end butting.

Terry Stewart

Shaker Products Distribution and Services

Willow Spring, North Carolina