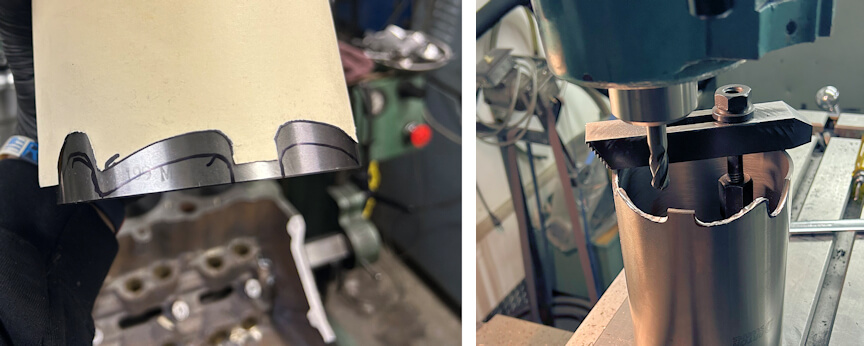

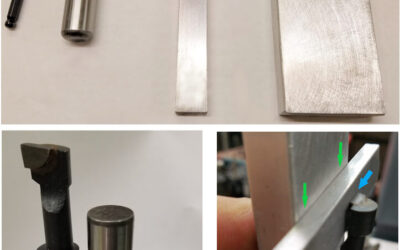

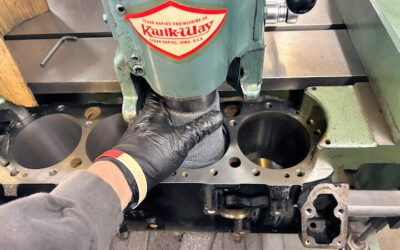

When sleeving blocks that have stroker clearance work done, I make a pattern from the bore ID and transfer it to the sleeve. This allows me to do most of the clearance work to the sleeve before installation using the mill. Find a reference mark on the block and draw lines to align the sleeve when installing. This really reduces the overall time to finish. Ductile liners are a lot of work to do by hand, so this really helps.

Ron Flood

Cedar Machine

North Branch, MN