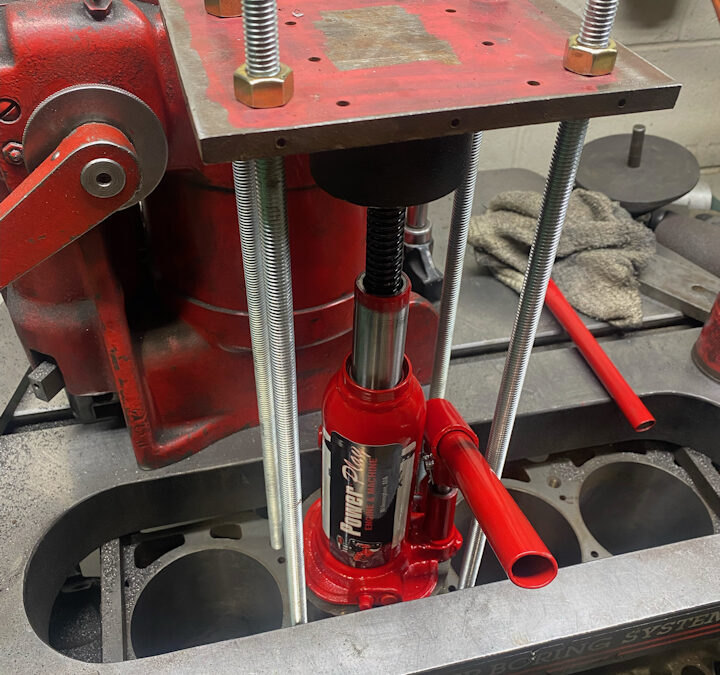

Sometimes when chasing the head bolt holes on Chevy blocks, you'll hit a casting knob. Then you think, will the bolt thread in far enough. I use a 7/16 valve guide and some washers to mimic the cylinder head thickness. This saves time by not having to measure every...