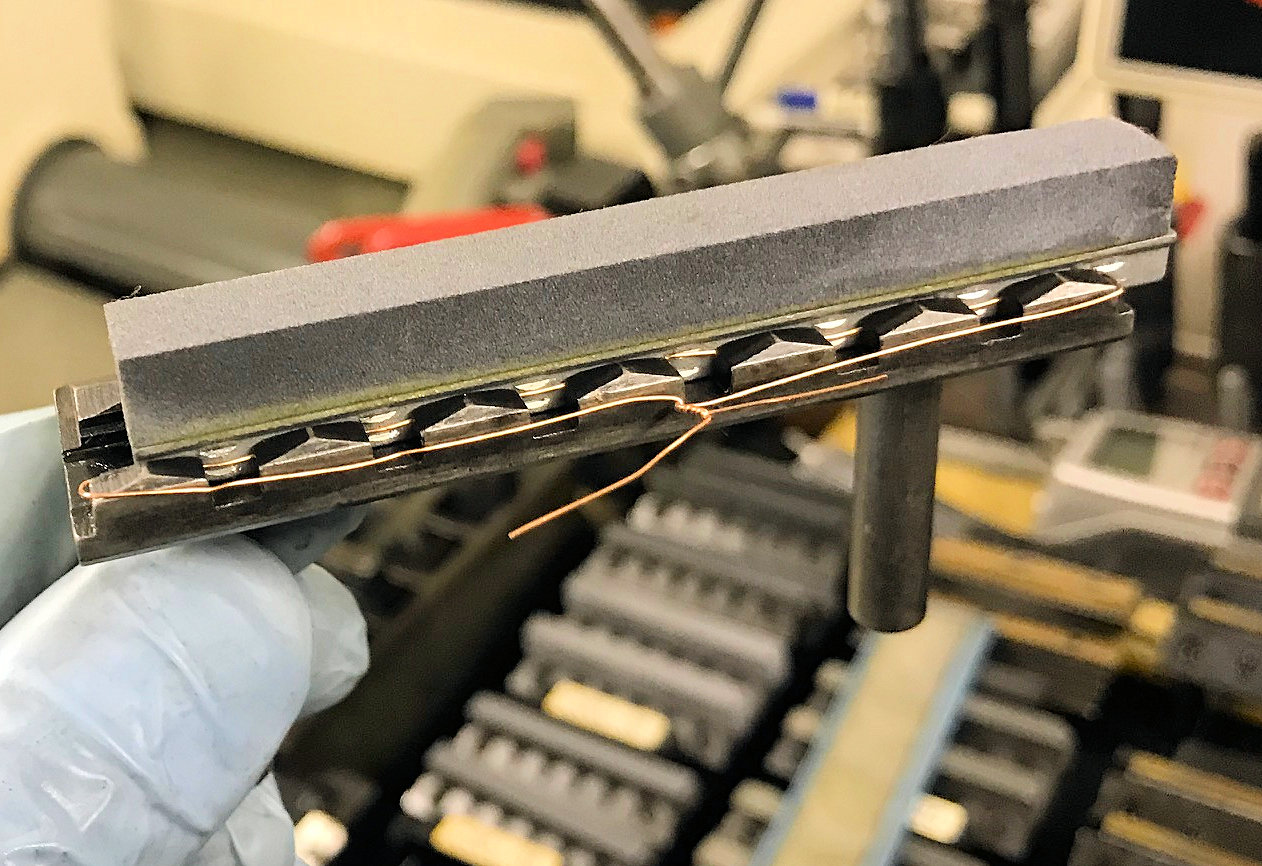

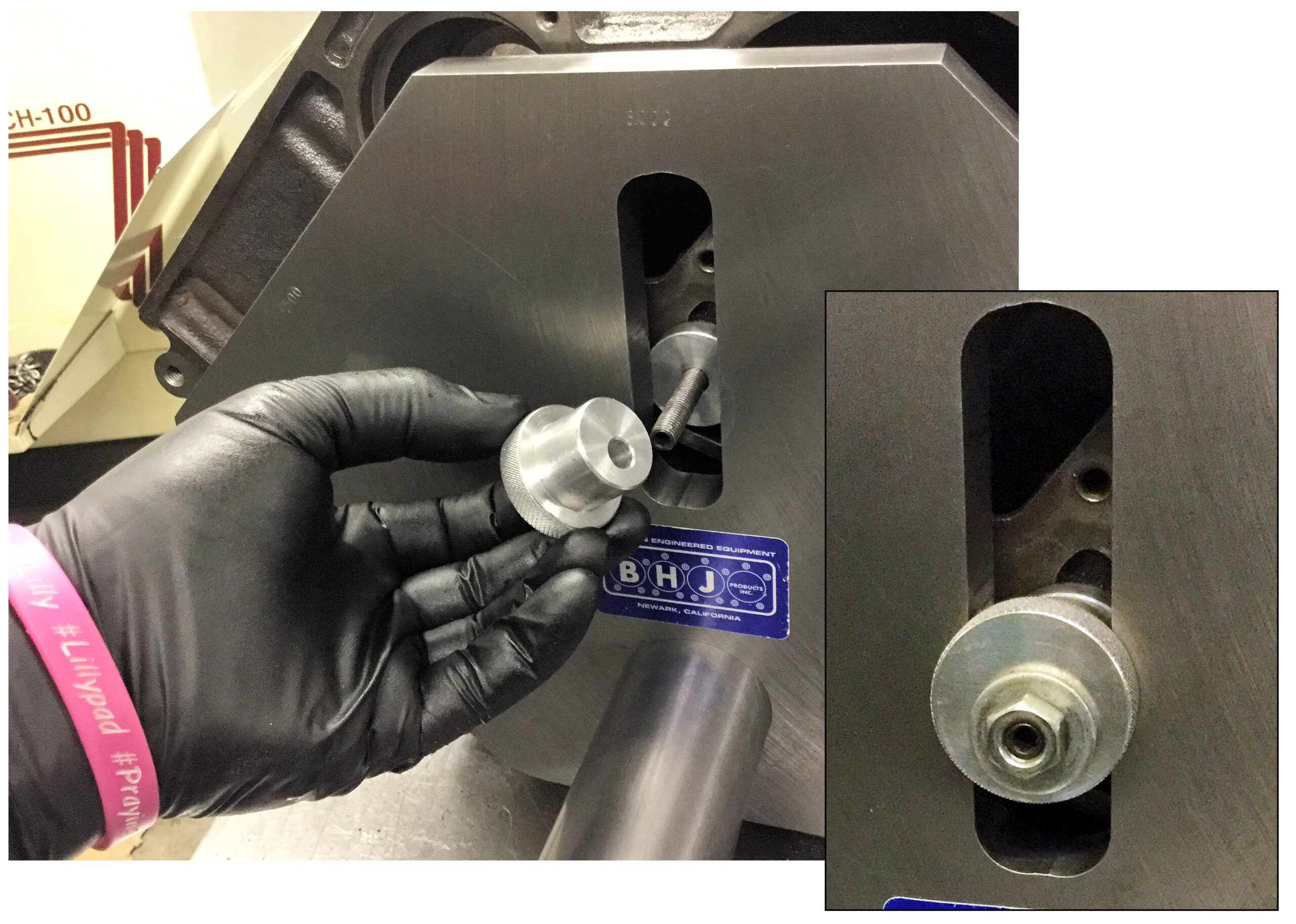

SLEEVE LOCKS When boring and honing engines with sleeves that have only a light press fit, we have found that the torque from the honing operation may cause the sleeve to slip in the engine case. We use 4 old 4-sided carbide inserts and some clamp bolts and nuts from...