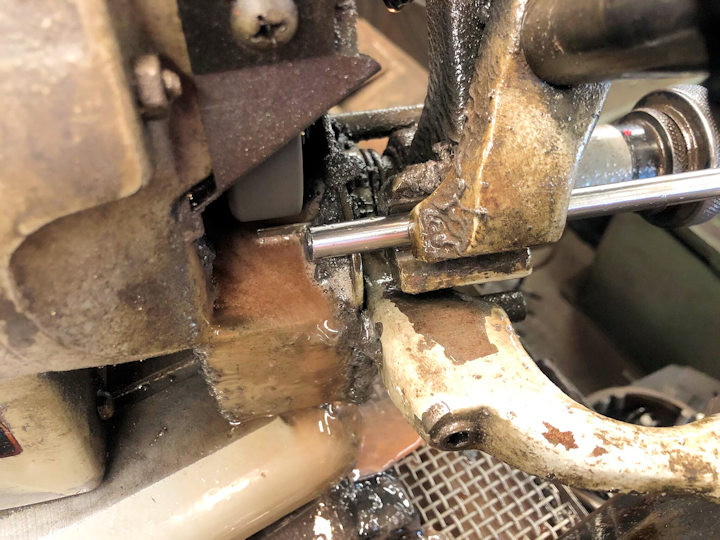

When breaking in flat tappet cams, I place these Rare Earth Magnets on the top of the outer head bolts, and I'll use break-in rocker arms when the open pressure is high. These and a magnet on the drain plug let me keep an immediate eye on ferrous metal, and I send off...