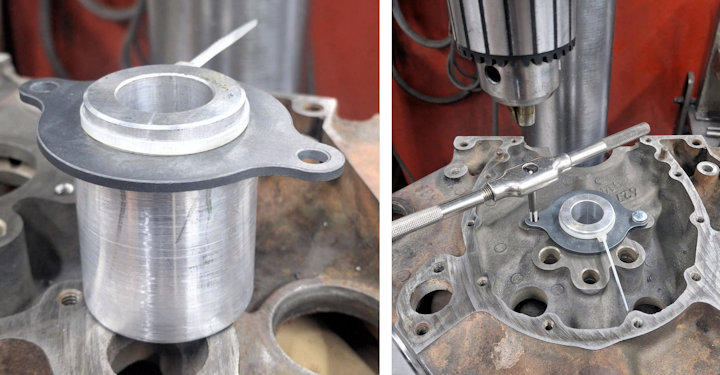

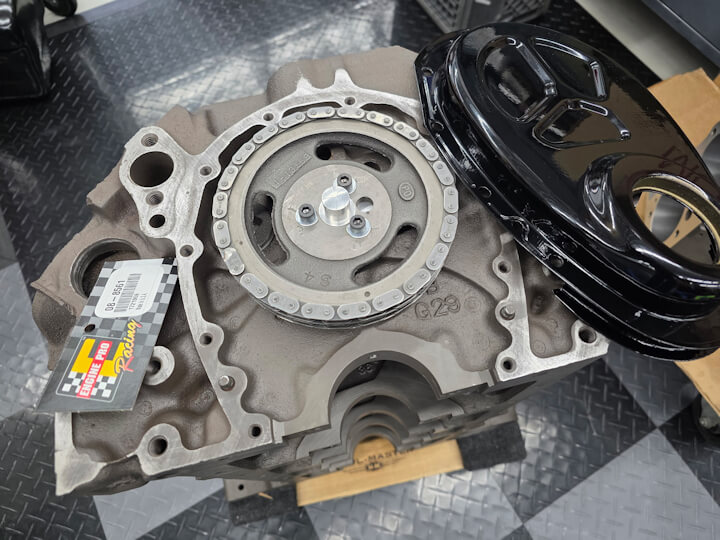

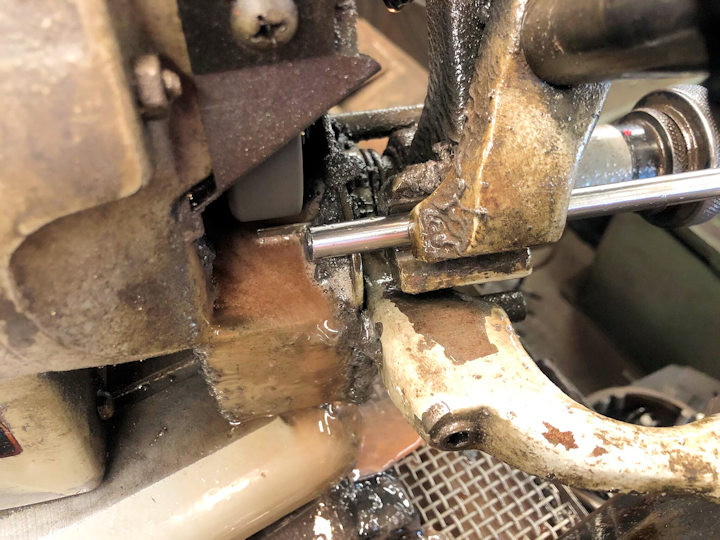

In order to correctly locate and drill a small block Chevy block for an O.E. cam thrust plate, we made a jig from an aluminum leaf spring bushing. It locates in the cam bearing bore, and the top is machined for the I.D. of the thrust plate. It works like a charm! Rich...