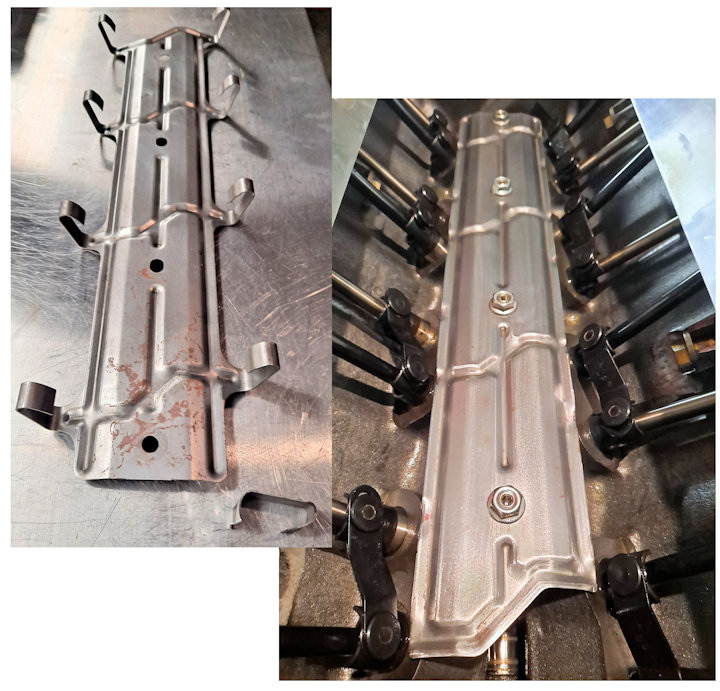

When checking valve train geometry, you need adjustable pushrods which are never the right length and you need to use a light spring. I bought 1 of every 3/8 .080 wall pushrod 7.00” to 12.00”, in .050” length increments. It makes checking geometry quick and easy. Bob...