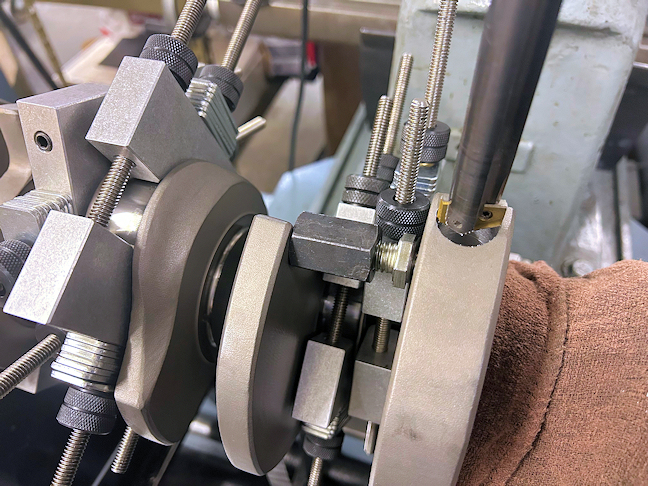

When drilling on cranks for balancing, install a simple jackscrew between the counterweights to eliminate flex at the rod journal. I use the same ones for drilling in line with the crank for heavy metal install, if the counterweight is unsupported on the drill...