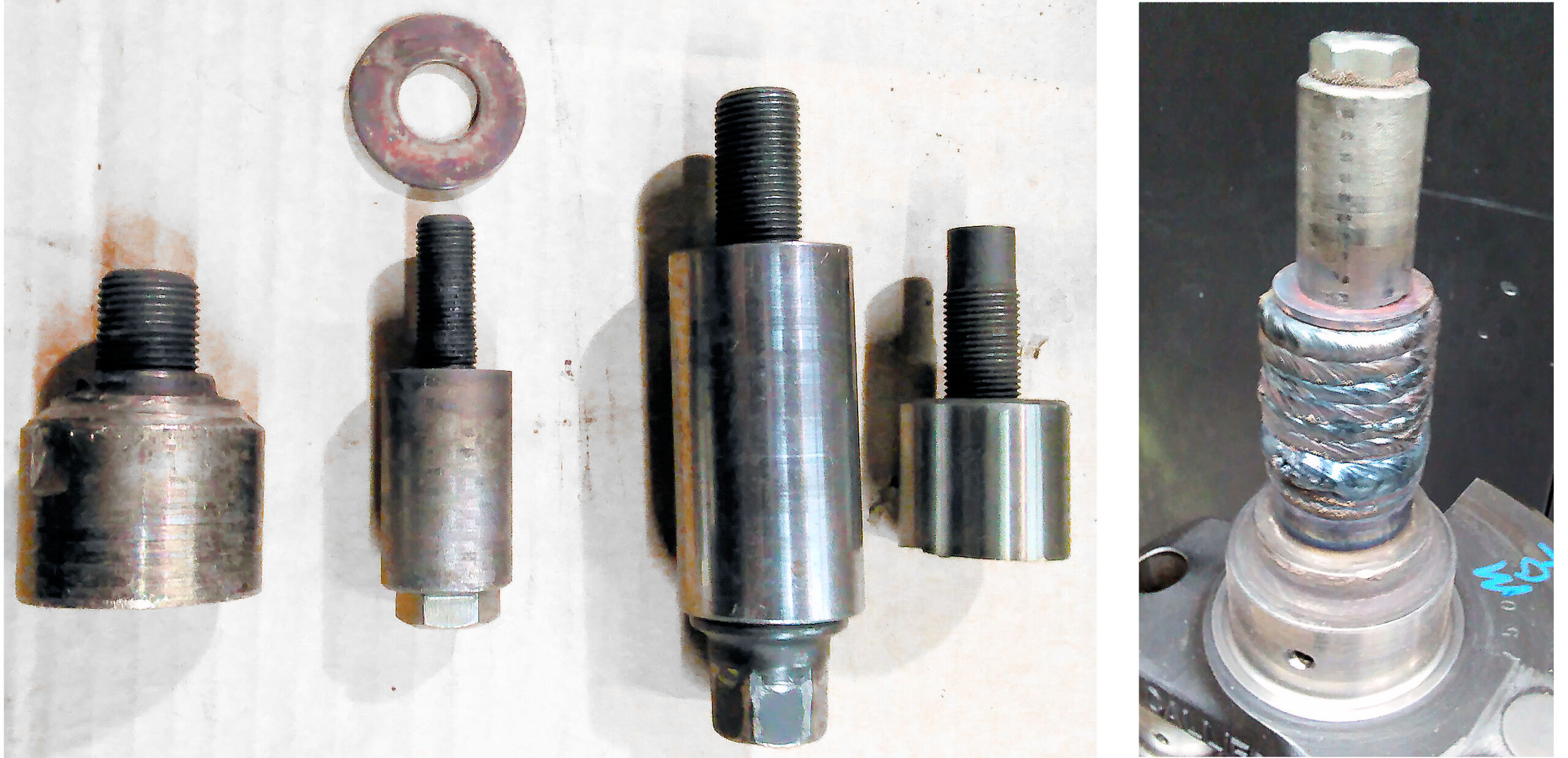

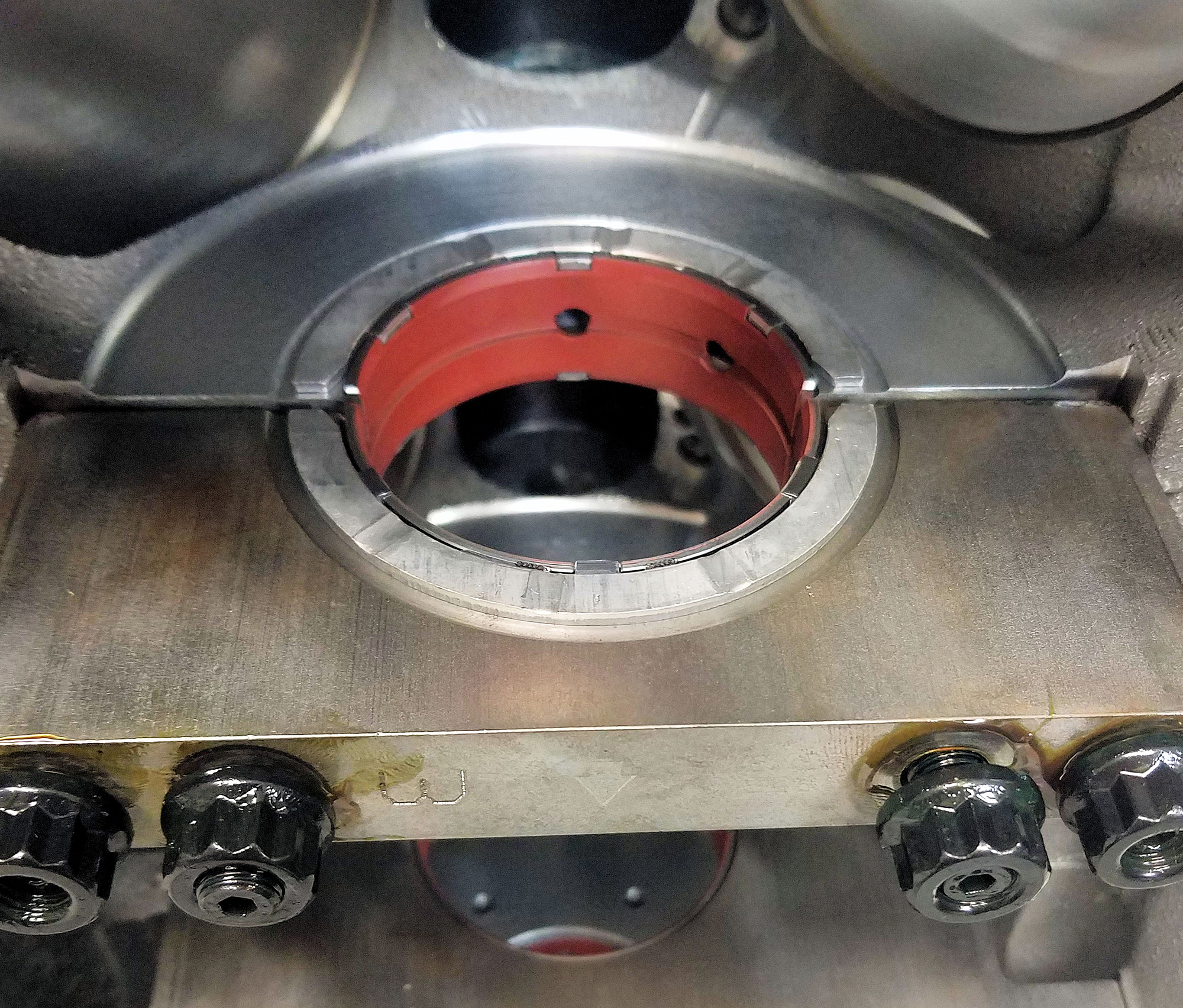

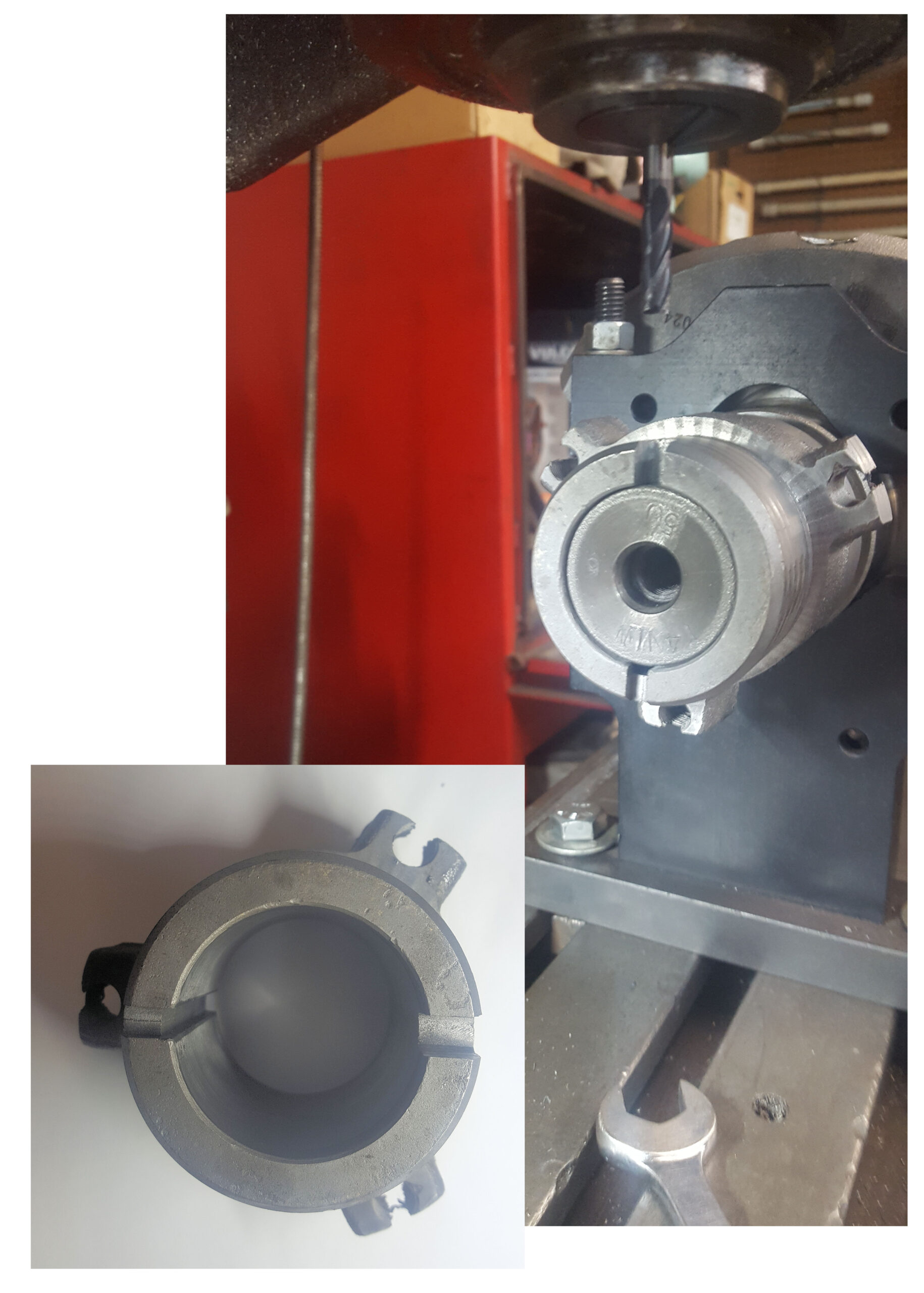

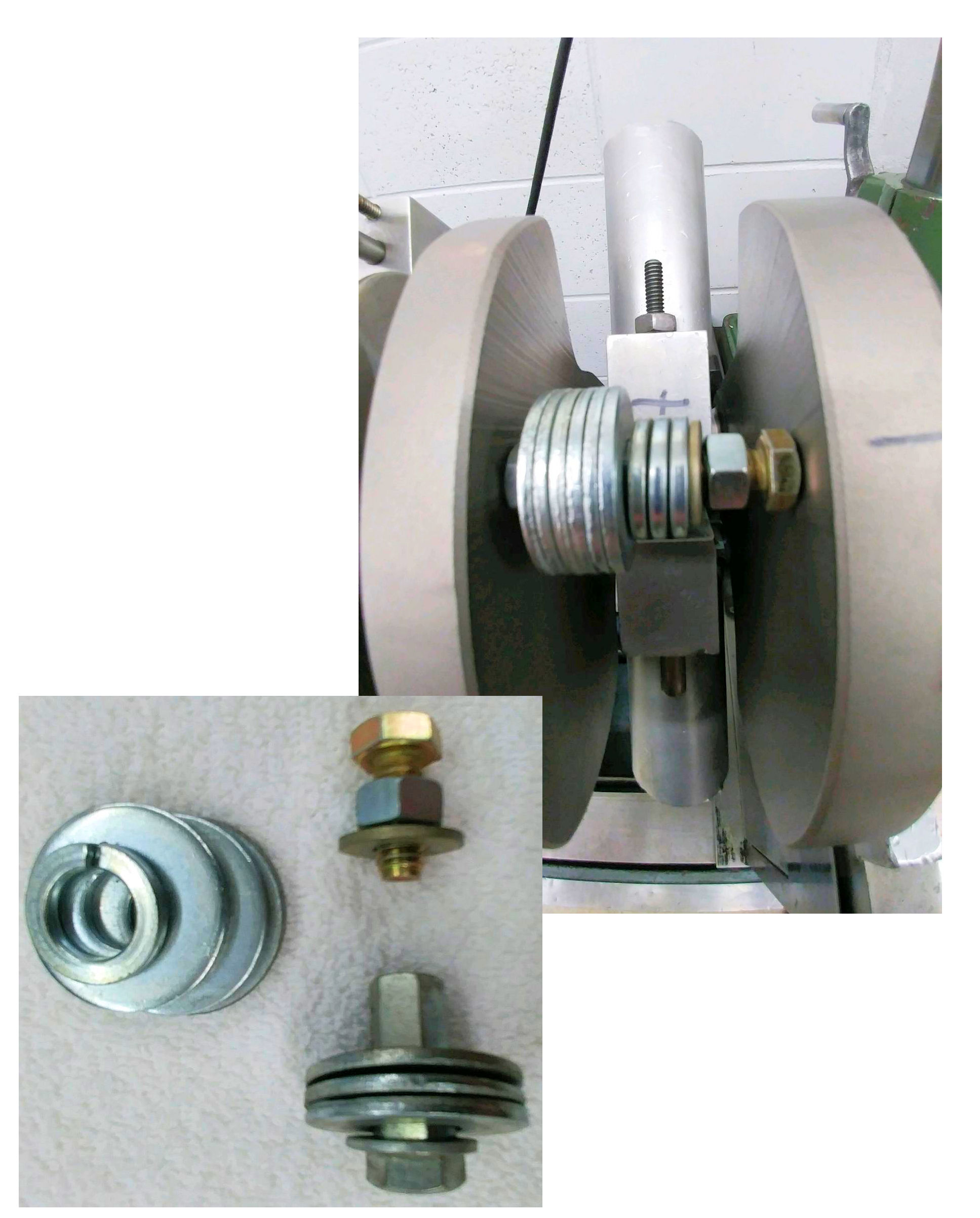

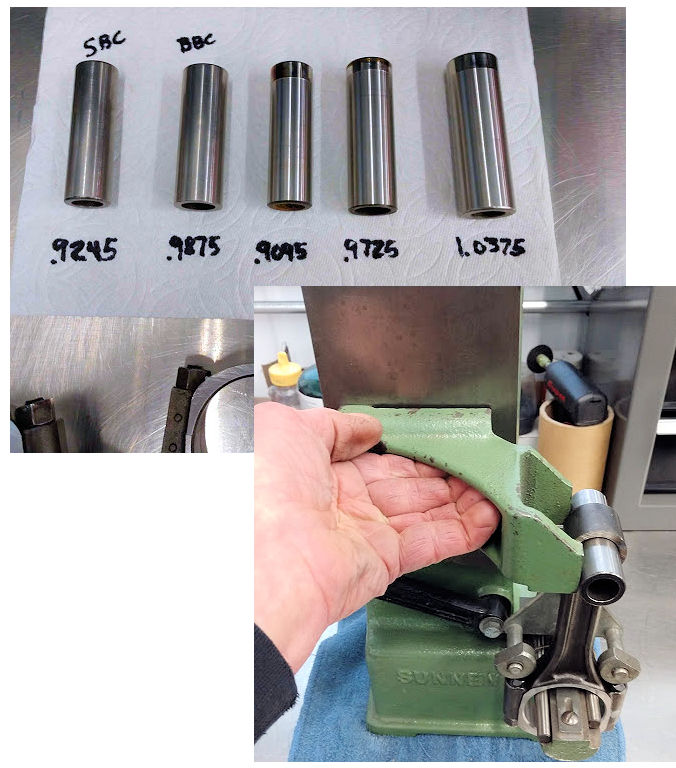

ANOTHER HOMESPUN MANDREL We do a lot of crankshaft snout rebuilding. To make the process easier we keep some homespun mandrels that screw into the snout of the crankshaft so it is held secure for welding and machining. Also, by using a copper washer between the...