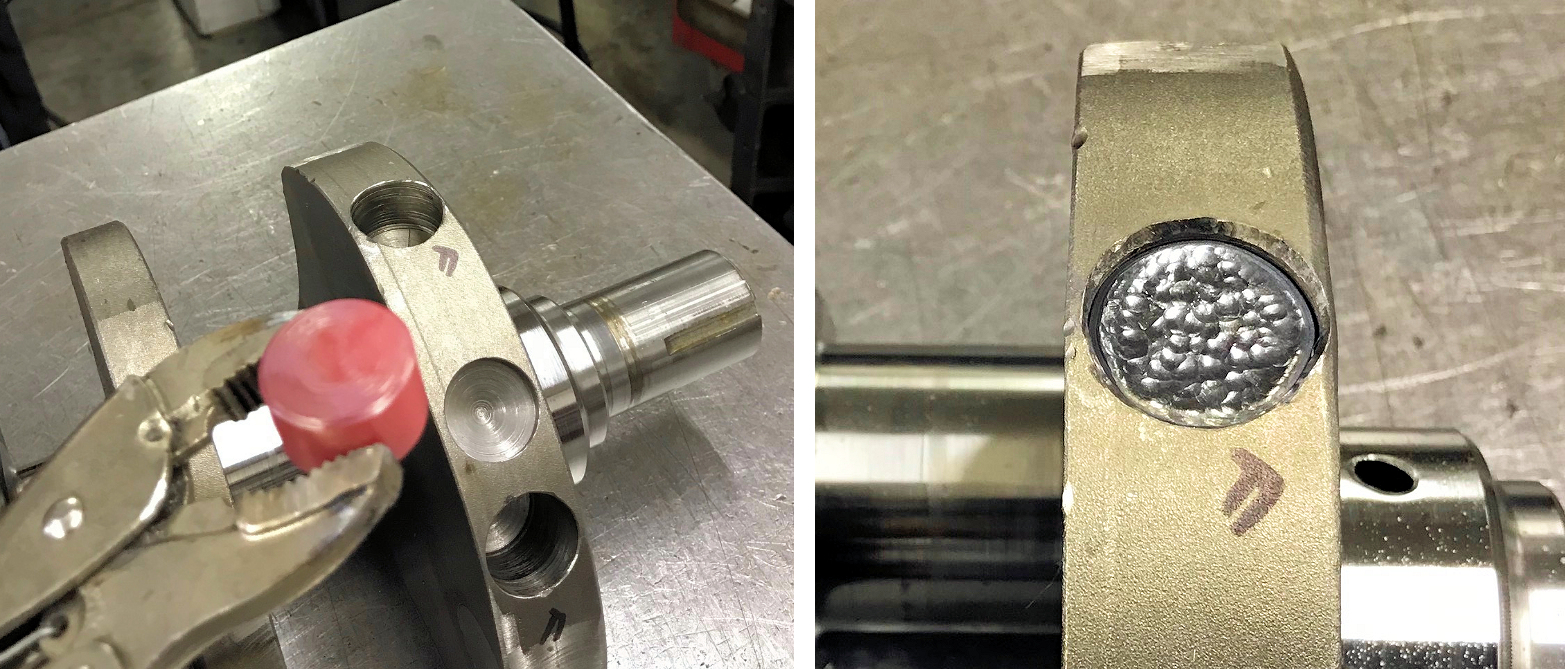

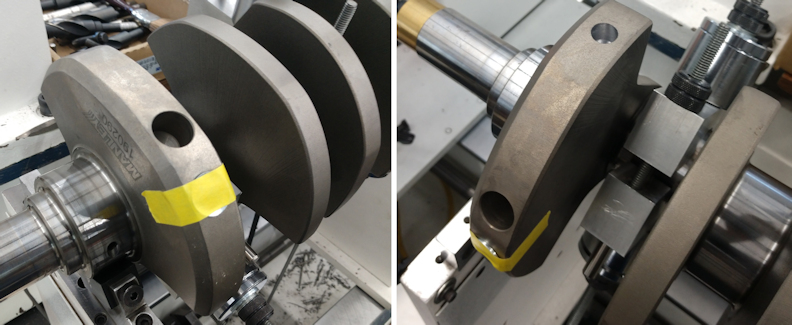

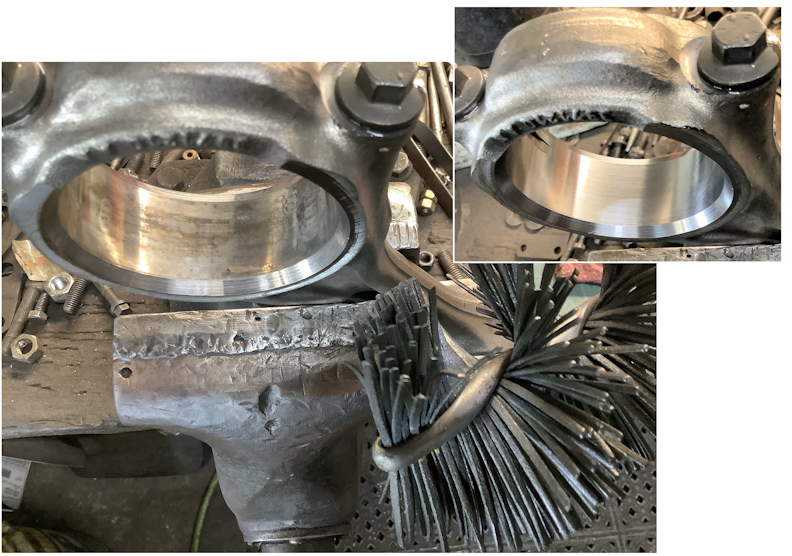

PRIMING PUMP You can make a GM-LS engine priming tool using just about any oil pump. I used a new big block Chevy M77 pump that I already had. I tapped the inlet and outlet to NPT threads and installed fittings to adapt to rubber hoses. The pressure side needs to...