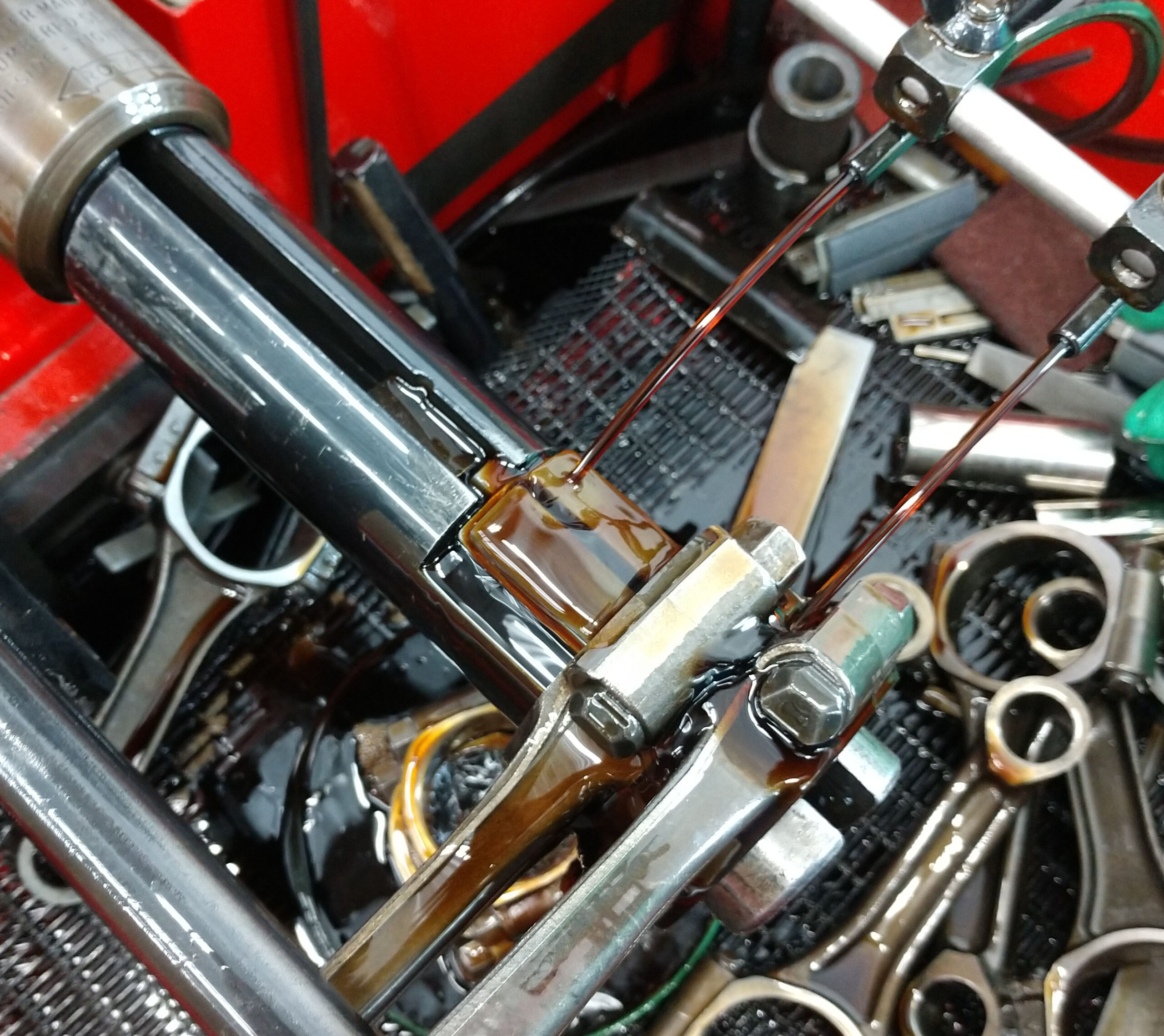

CRANK BALANCE SOCKET If your shop has a particular crankshaft design you tend to balance on a regular basis, we recommend using a crankshaft snout socket as a locator on your magnetic attachment for rpm and position on your balancer. This allows you to quickly remove...