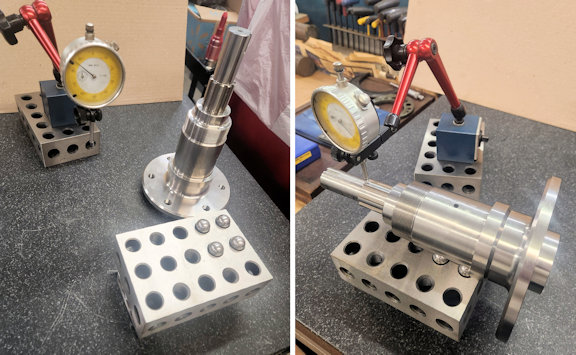

Here’s an easy fixture for inspecting run-out on shafts with a diameter too large to fit in your V-blocks. We place 2-4-6 blocks (or you can use a couple of 1-2-3 blocks) on our granite surface plate. You could also use a mill table. Next drop 4 steel ball bearings...