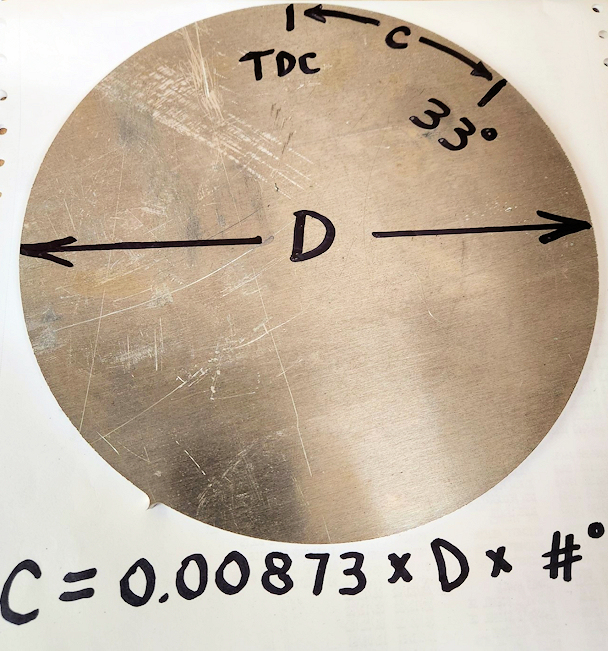

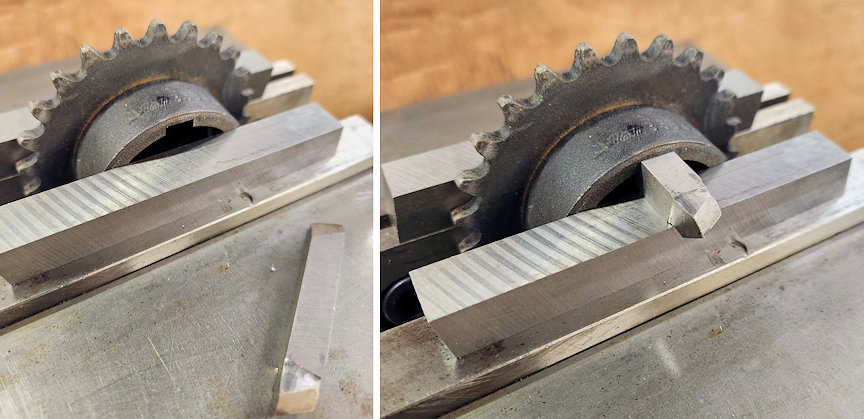

Timing marks on pulleys can be relocated by using the following formula: C = Pulley Diameter x 0.00873 x #° Where: #° = the number of degrees the timing mark is to be moved along the rim of pulley. On pulleys 6" and greater, with moves of 30° or less, a dial caliper...