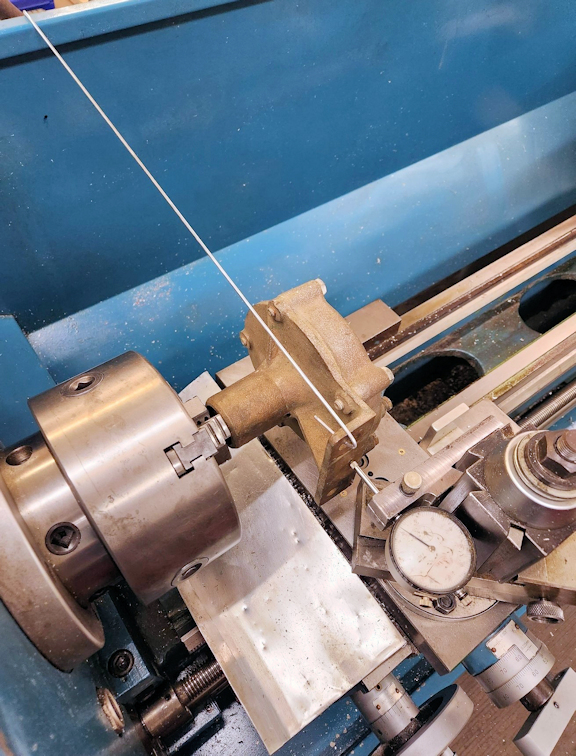

THE WIGGLER When using a wiggler to center a mill spindle on a center punch mark or layout lines, many machinists use a pencil to push on the wiggler's pointer, until it runs true. However, risk of injury occurs when the pointer is pushed a tiny bit too far, and...