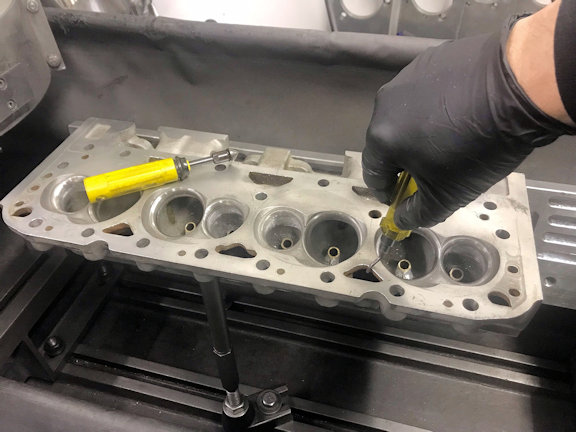

CLEAN CUT When surfacing blocks or heads, it’s a good idea to deburr all the water jacket and bolt holes before making cuts. Many heads have scale and residue on those areas that can cause “drag” marks when the tool bit passes over. Marine heads, or any head that’s...