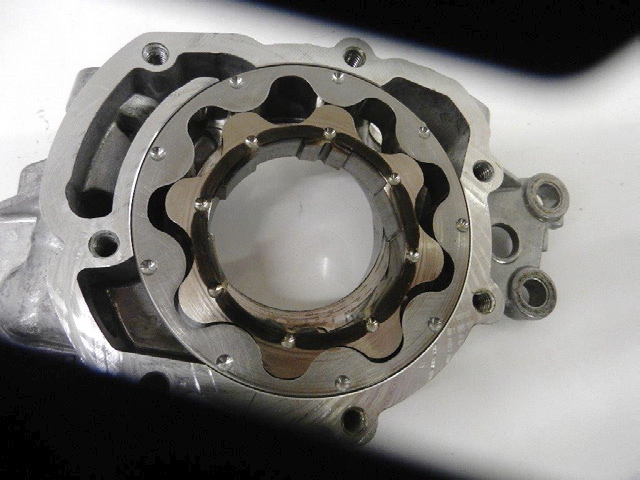

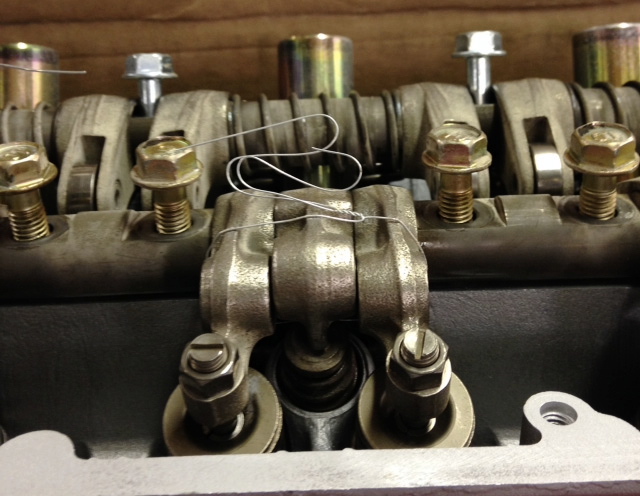

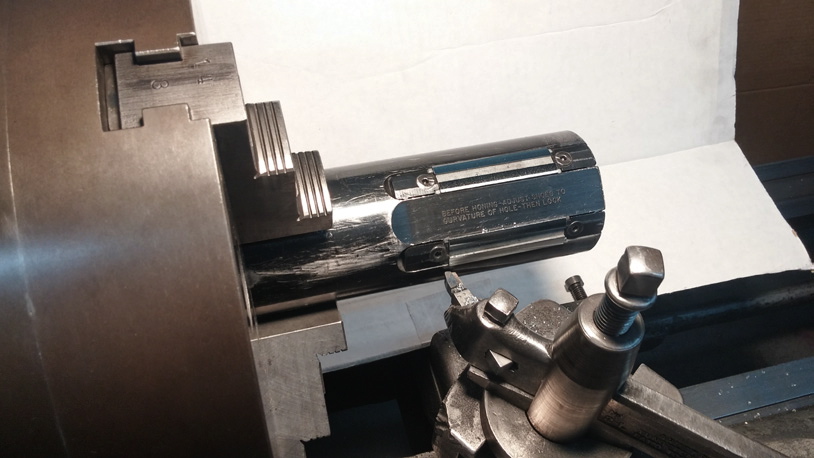

GM LS-Series Double-Roller Chain Oil Pump Spacer Warning If you are using a spacer to reposition the oil pump forward in a Chevy LS engine so that a double-roller chain can be installed to drive the camshaft, use caution to make sure the pump has sufficient end play...