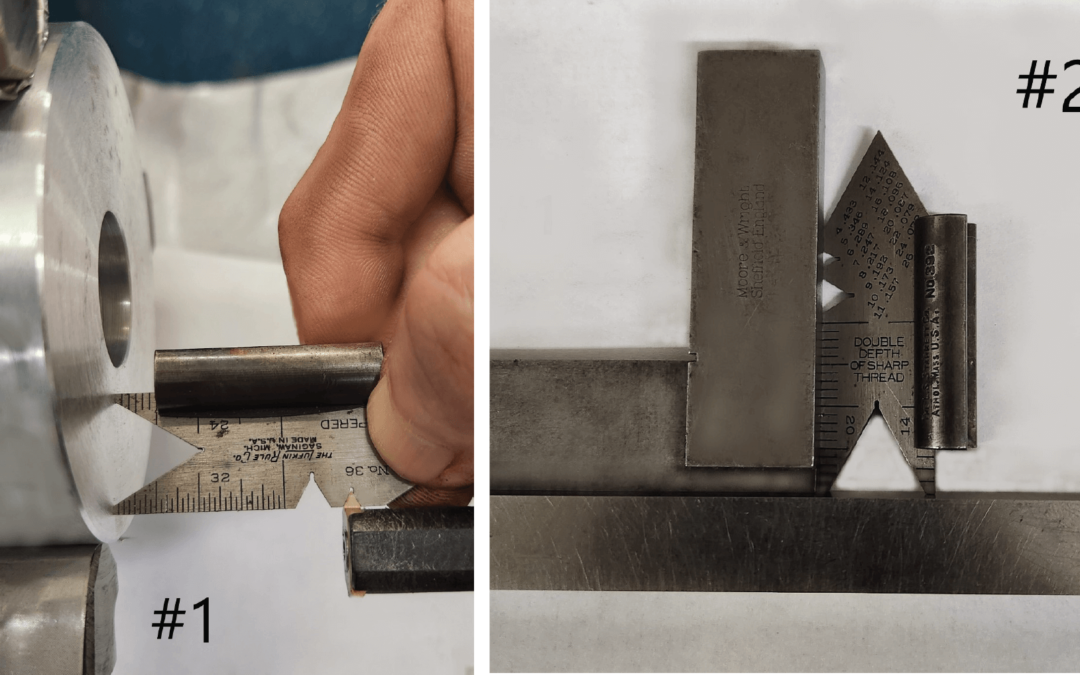

When machining threads on a lathe, a "Fishtail" is used to "square" the tool to the part. For external threads, the Fishtail's long edges are held against the O.D. of the part, while the tool is aligned to fit in one of the Fishtail's "V" notches. When cutting...