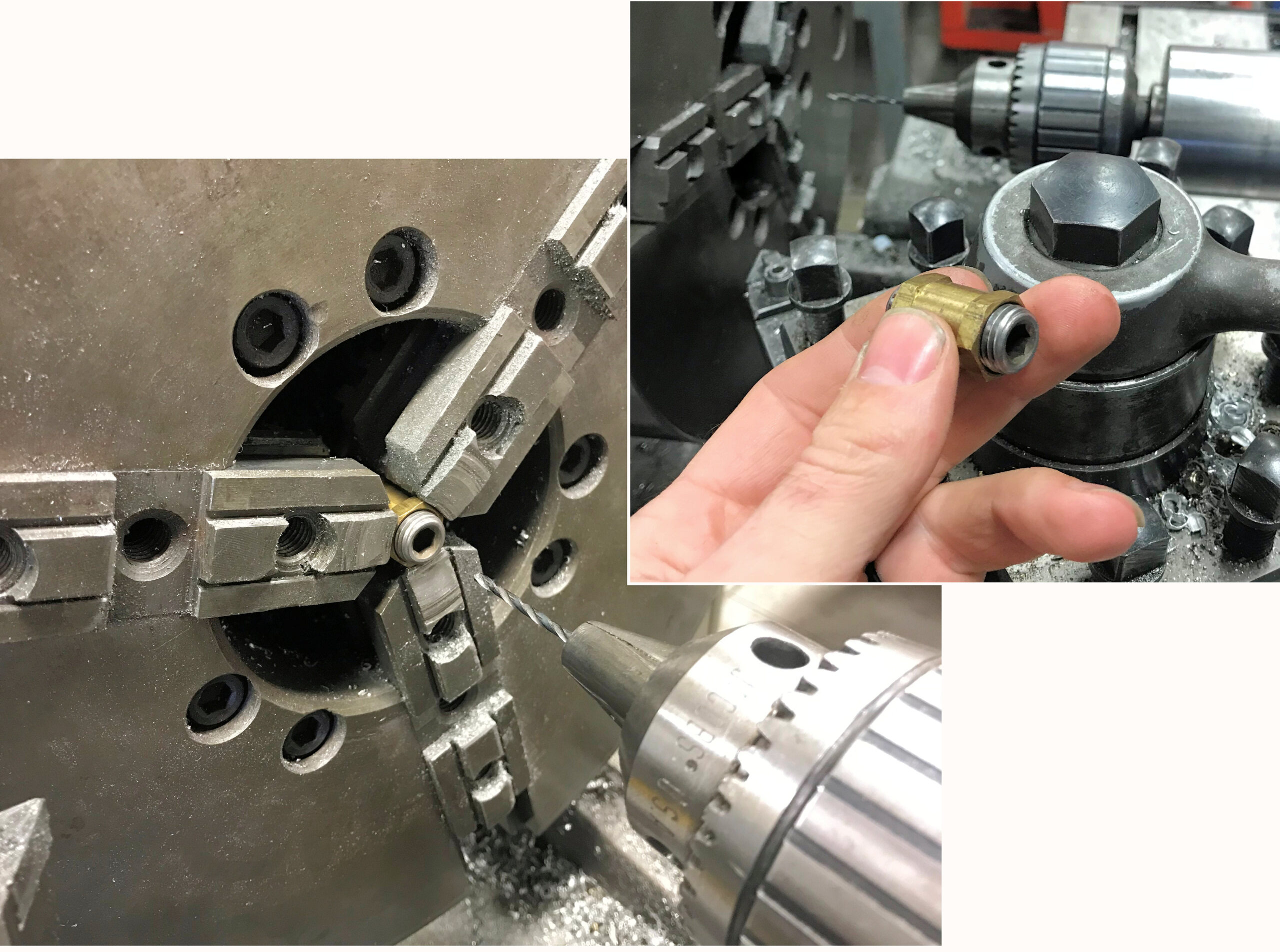

HANDY HOLE TRANSFER PUNCHES When fabricating gaskets, exhaust flanges, etc. , a set of hole transfer punches can make the job easier. However if you do not have transfer punches, or if they're always at the other end of the shop, this little trick comes in handy. Set...