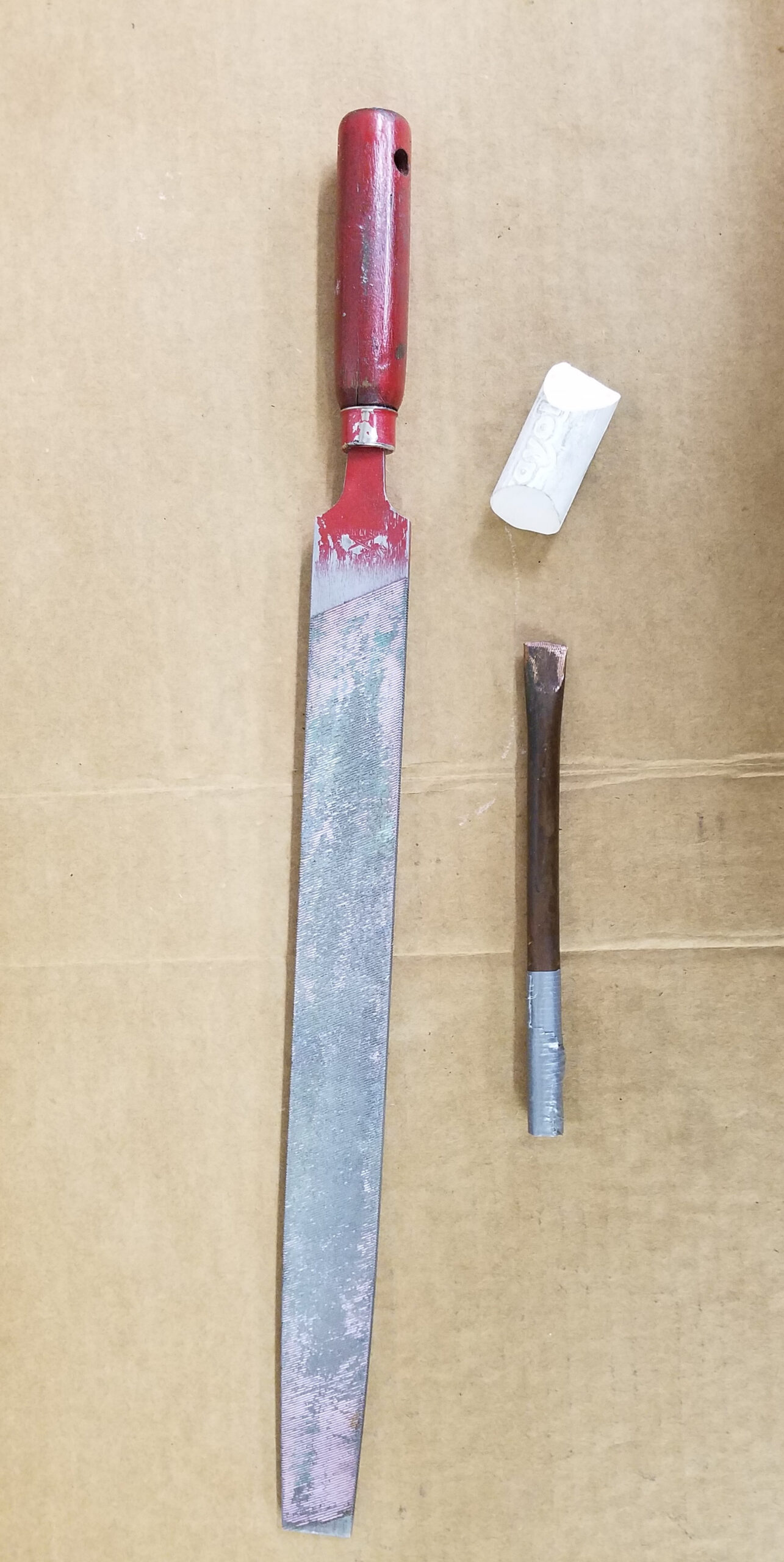

CHALK UP ANOTHER TIP To prevent a clogged file from marring your work, try filling the file's teeth with chalk. Children's sidewalk chalk works well for this. Should the file become clogged, a length of 3/8" or 1/2" copper tubing, with one end flattened, will quickly...