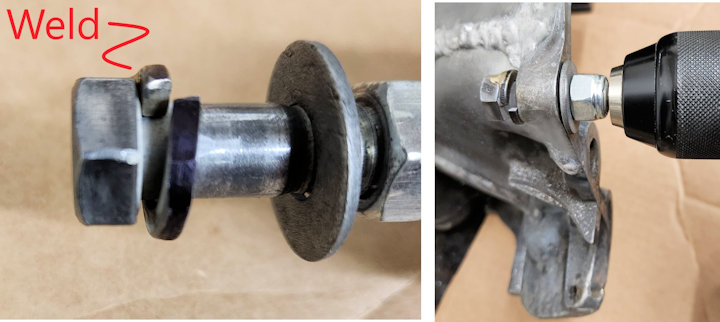

Up against a deadline to ship engines, we elected to machine the 20 chrome water necks to fit, rather than return them and order more. To securely hold the water necks in our lathe, we needed a custom-sized expanding arbor. I made the arbor from a 4" length of...