CYLINDER SUPPORT

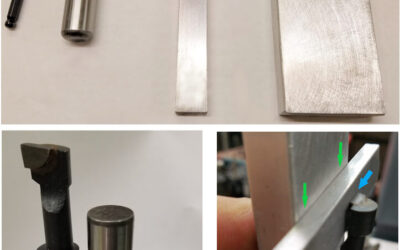

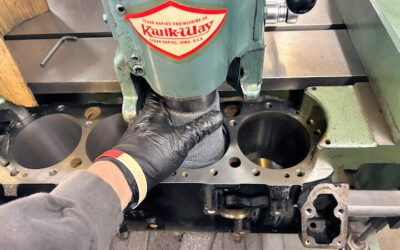

Honing motorcycle or power sport cylinders can be difficult. The thin bottom portion of the cylinder often protrudes 1”-3” below the cylinder assembly and if this thin/bottom portion of the cylinder is not supported during the honing process, the hone tends to push the cylinders outward instead of removing material. Thus resulting in a bore that is smaller at the bottom of the cylinder than the top. If you have an unused or obsolete torque plate that you are not using, you can easily build a support for the cylinder: Measure the bore of the crankcase that the cylinder is going into with a dial bore gauge. Then, using your boring bar, set your boring bar cutter to the same size and bore the torque plate. If the inside diameter of your torque plate is larger than the outside diameter of the cylinder or if the cylinder is longer than the torque plate you can install a cylinder sleeve to adjust for size or length. Honing with the cylinder installed in your new fixture will simulate the support of the crankcase on the bottom of the cylinder.

Dave Matton

D and D Auto Machine

Bloomington, MN

March, 2014