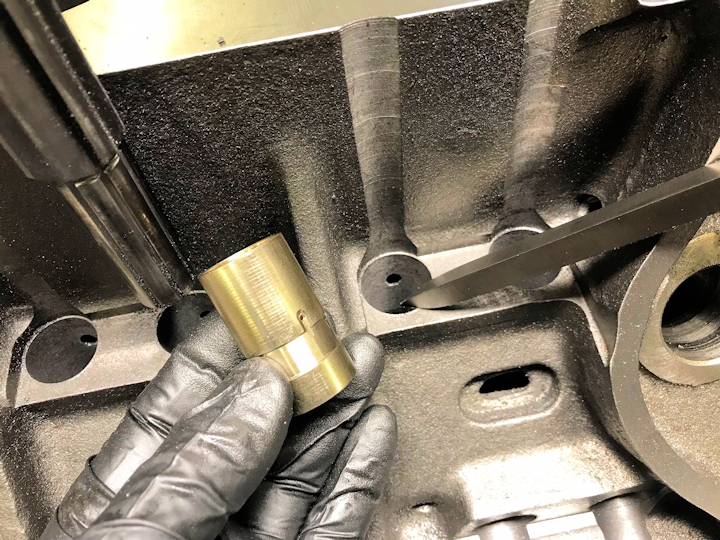

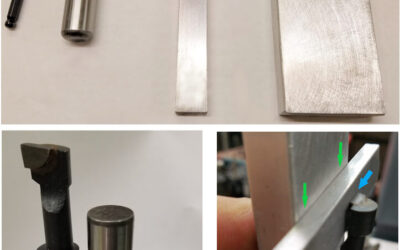

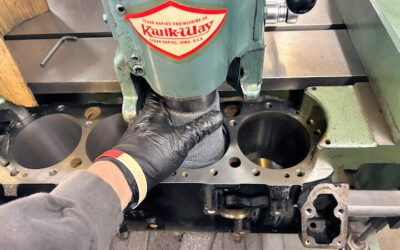

LIFTER BUSHING

When it comes to installing lifter bushings, heres a couple tips; Always deburr the top and bottom of the host bore, as well as any oil holes that intersect. This will prevent the dragging of material as the bushing is pressed in. A bearing scraper works excellent. Only use a light lubricating oil for install, as press fit lube can trap machining chips and honing grit and does not dissolve or flush out easily. This is mandatory with any bushing that has backside oil circuitry. In addition, make sure to polish and deburr any machining done to the lifter bushing. This is especially important with aluminum blocks, as any burrs can tear up the soft aluminum.

Ron Flood

Cedar Machine

North Branch, MN

FEBRUARY, 2024