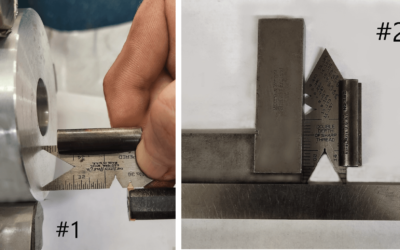

MINI GROOVES AND ACCUMULATOR GROOVES EXPLAINED

Piston ring second land accumulator grooves provide an area for escaping combustion gases and crankcase pressures, that get past the piston rings, to gather and dissipate. Without this feature, the passing compression losses or crank case pressure buildup could cause ring flutter, removing stable ring to cylinder wall seal. Mini grooves, machined into the top ring land are designed to trade off heat from the piston crown to the cylinder walls, should the piston crown become over- heated. The top land has multiple grooves machined into the land to cylinder wall face. These small lands are .010 in face width for less surface contact area. If the piston crown were overheated, they then touch the cylinder wall to exchange heat and hopefully save the piston from these damaging temperatures. They are also beneficial at disturbing violent detonation waves that could damage the top ring or the supporting second land. These mini grooves disturb the waves with the qualities of the irregular face surface and close proximity to the cylinder wall. Mini grooves may not be beneficial to top land durability in high boost applications due to higher than normal combustion temperatures. Sanding or turning back the face of the mini grooves so they are not as vulnerable to high temperature wicking of the nar- row .010 thousands faces is recommended. Sanding or turning the mini grooves back and diminishing the top land diameter will allow higher temperatures to operate on the edge of the top land. This will still allow some benefit against detonation by disturbing the detonation waves through the multiple lands of the now thicker faced mini grooves.

Engine Pro Tech Committee

with special thanks to United Engine & Machine Co. Silvolite, KB and ICON Pistons

January, 2016