Piston Ring Gapping Tip

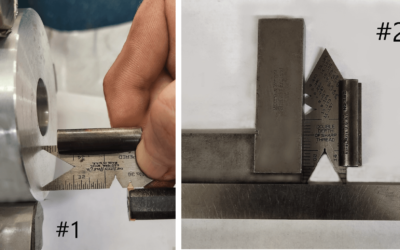

Some of you may know this ring end gapping tip, but I have never seen it anywhere. Not even in ring package instructions. This has to do with checking the flimsy oil rail gaps. Most conventional size bores are not much of a problem. The rails on those sizes usually have a lot of leeway. But, when you do some odd, custom bore sizes, the ring package may be a closer fit, and out of the box the oil rails tend to have closer gaps and need more clearance. Under these circumstances, it is much harder to measure the rail gaps accurately. For example, I am building an engine right now that inspired me to write this tip. It is a Ford 428CJ. It was already +.040 ̋ (4.170 ̋). My customer wanted a Scat stroker kit. I instructed Scat to make the pistons .045 ̋ over for the kit, for a bore of 4.175 ̋. The extra .005 ̋ would clean up some irregularities and scuffs and afford me enough to torque plate hone to a perfect tolerance. When the stroker kit arrived, it included the file fit Total Seal special size rings necessary for the odd size bore. The Total Seal instructions required minimum .015 ̋ gap for the oil rails. The engine is for a frame off restored ‘63 Ford Galaxy street cruiser. It will use premium gas with perhaps a touch of octane booster. No power adders, so no wide ring gaps. Gapping the two top rings was an easy job. They only took about nine cranks each using my old manual ring grinder. The Total Seal instructions required a minimum .015 ̋ gap for the oil rails. It is not easy to measure a thin .024 ̋ x .132 ̋ wide rail with that narrow of a gap on a large bore. When I squared one in a bore, the gap looked pretty narrow. It was impossible to snug a feeler gauge in the gap without disturbing the ring. Here is what I did; I took the 1/16th thick stiff top ring, which I had already gapped to .020 ̋, and squared it back in the cylinder. Then I placed the oil rail on top and lined up the two gaps. Gently, but firmly, I used my squaring device to snug the rail firmly atop the 1/16 ̋ ring. That keeps the oil rail square and tight and does not squirm or fold up when checking it with a feeler gauge. I was able to fit a feeler gauge snug in the rail gap. I was thrilled! The gaps were .017 ̋. That would be perfect. No way could I have measured it that accurately without the 1/16th ring supporting the rail. Needless to say, the same can be done with gapless rails or exotic thin rings or spacers. A used top ring can be used for support if it is the proper size. It can be gapped wider to make lining the two ring gaps easier. For this 428 with an odd size bore, I just used the new gapped top ring for the supporting role. No pun intended!

Jim Feurer

Animal Jim Racing

Lacon, IL

December, 2013