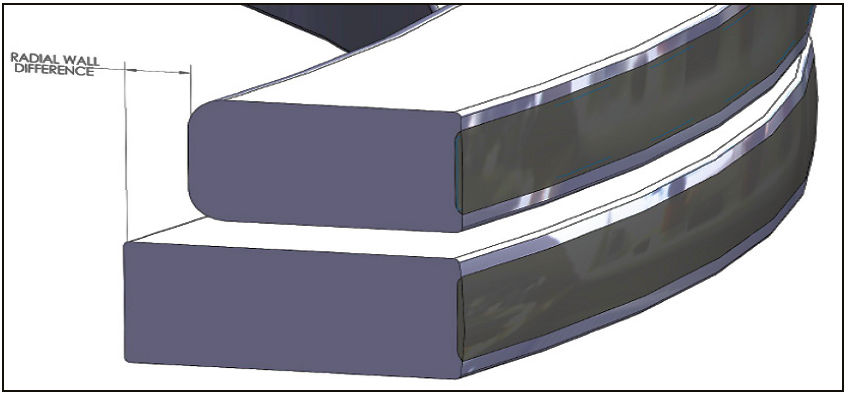

REDUCED RADIAL WALL BY DESIGN

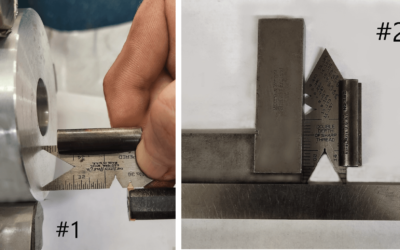

The use of steel in the upper compression ring has many advantages. Steel provides 35% more strength, weighs 30% less and increases the resistance to side wear, which is observed on the newer model engines. Another feature from the increased steel strength is the insensitivity to breakage during improper ring installation. ** The increased strength of steel over grey cast iron means that necessary tension can be achieved with less weight. This increased strength feature allows production of high quality rings with reduced radial walls. Increased strength, reduced radial wall and lighter weight all improve the performance of the compression ring. Newer engines have higher RPMs and lighter rings that are more stable in the groove. Improved sealing is achieved by the steel compression rings conforming to the cylinder better. ** Original equipment piston ring grooves and ring designs take into consideration the ring back clearance. It is thought that minimal ring back clearance improves overall performance of the engine. The power stroke gases energize the compression ring increasing the pressure against the cylinder wall, decreasing blow-by and increasing power. The concern that increased ring back clearance will adversely affect engine performance has been dismissed by engine testing. In summary, modern engines are insensitive to increased ring back clearance. ** The important features of piston rings are the correct axial width and optimal gap. The correct side clearance is typically in the .0015” – .0025” range. This is adequate side clearance to allow the compression gases to energize the ring to operate properly. Builders can replace cast iron top rings with steel top rings and get all the benefits discussed without fear of the new reduction in radial wall depth.

Engine Pro Technical Committee ** With special thanks to Hastings Manufacturing Company

March, 2017