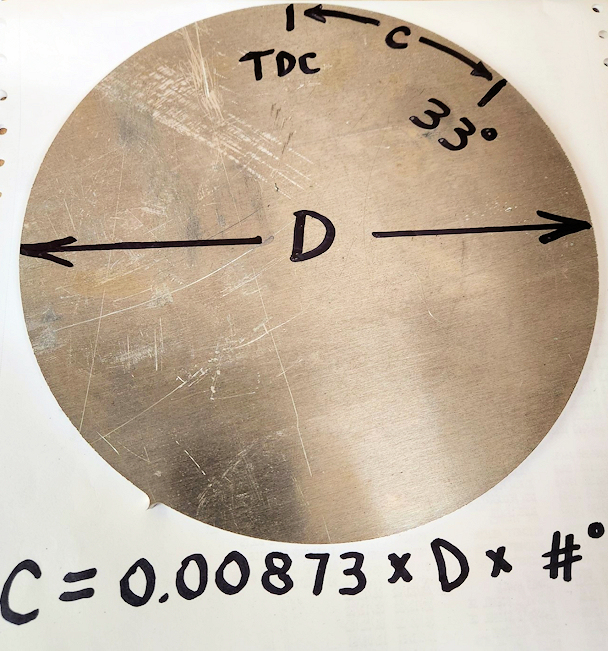

Timing marks on pulleys can be relocated by using the following formula:

C = Pulley Diameter x 0.00873 x #°

Where:

#° = the number of degrees the timing mark is to be moved along the rim of pulley.

On pulleys 6″ and greater, with moves of 30° or less, a dial caliper can be used to layout distance C, since the difference between the chord length vs circumference distance difference is very small. For smaller pulleys or greater number of degrees moved, “C” can be divided and marked out in small segments. For example, on a 6″ pulley a 15° circumference arc’s length (C) is 0.00873 x 6 x 15 = ~ 0.7857”. The chord length is 6″ x sin (15°/2) = ~ 0.7832″. The difference is 0.7857 – 0.7832 = 0.0025″, which is well within tolerance for most applications. The example in the photo is relocating the timing mark to 33°. Nobody said shop math was easy … just handy.

Tom Nichols

Automotive Machine & Supply, Inc

Joshua, TX