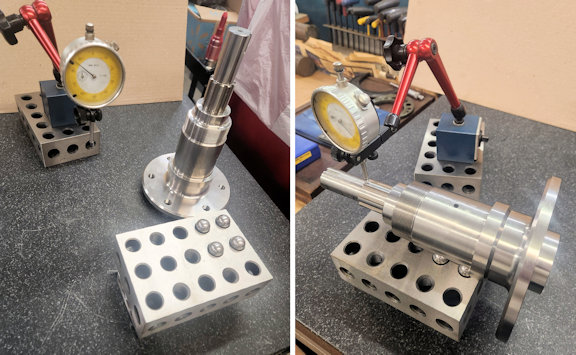

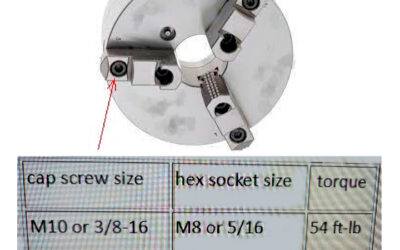

Here’s an easy fixture for inspecting run-out on shafts with a diameter too large to fit in your V-blocks. We place 2-4-6 blocks (or you can use a couple of 1-2-3 blocks) on our granite surface plate. You could also use a mill table. Next drop 4 steel ball bearings into the holes in the 2-4-6 block and nest the shaft on the balls to simulate a larger V-block. In these pics, we placed 1-2-3 blocks under the 2-4-6 block to raise the propeller shaft enough to allow the prop mount flange to clear the surface pate. Another 2-4-6 block was used to “anchor” our indicator’s magnetic base.

Tom Nichols

Automotive Machine & Supply, Inc

Cleburne, TX