A DIFFERENT CAM BEARING FIT

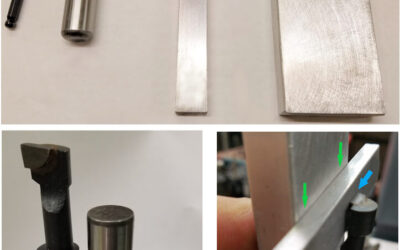

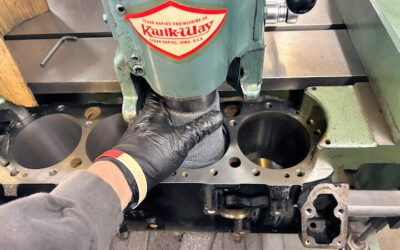

Most if not all OEM blocks were fitted with semi-finished cam bearings and then the I.D.”s were bored in place. Many suffer from poor factory size issues. This situation can lead to tight or no bearing clearance when finished cam bearings are installed. While correcting the housing bores is the preferred method, here are a couple of ways to get them to fit if that isn’t an option. Simply mic up the tight bore and turn the OD of the bearing on an arbor or spud in the lathe to achieve a .004” press. Another option is to belt sand the OD to achieve the proper press. It’s pretty easy to remove a few thousandths very accurately, even by hand. Of course, this won’t correct any housing bore misalignment issues, but it’s a better alternative to scraping or using a “cutter cam” where it’s a simple bore size issue. It also allows you to use coated bearings in an application that you otherwise could not, because of the need for I.D. sizing.

Ron Flood

Cedar Machine

North Branch, MN

April, 2021