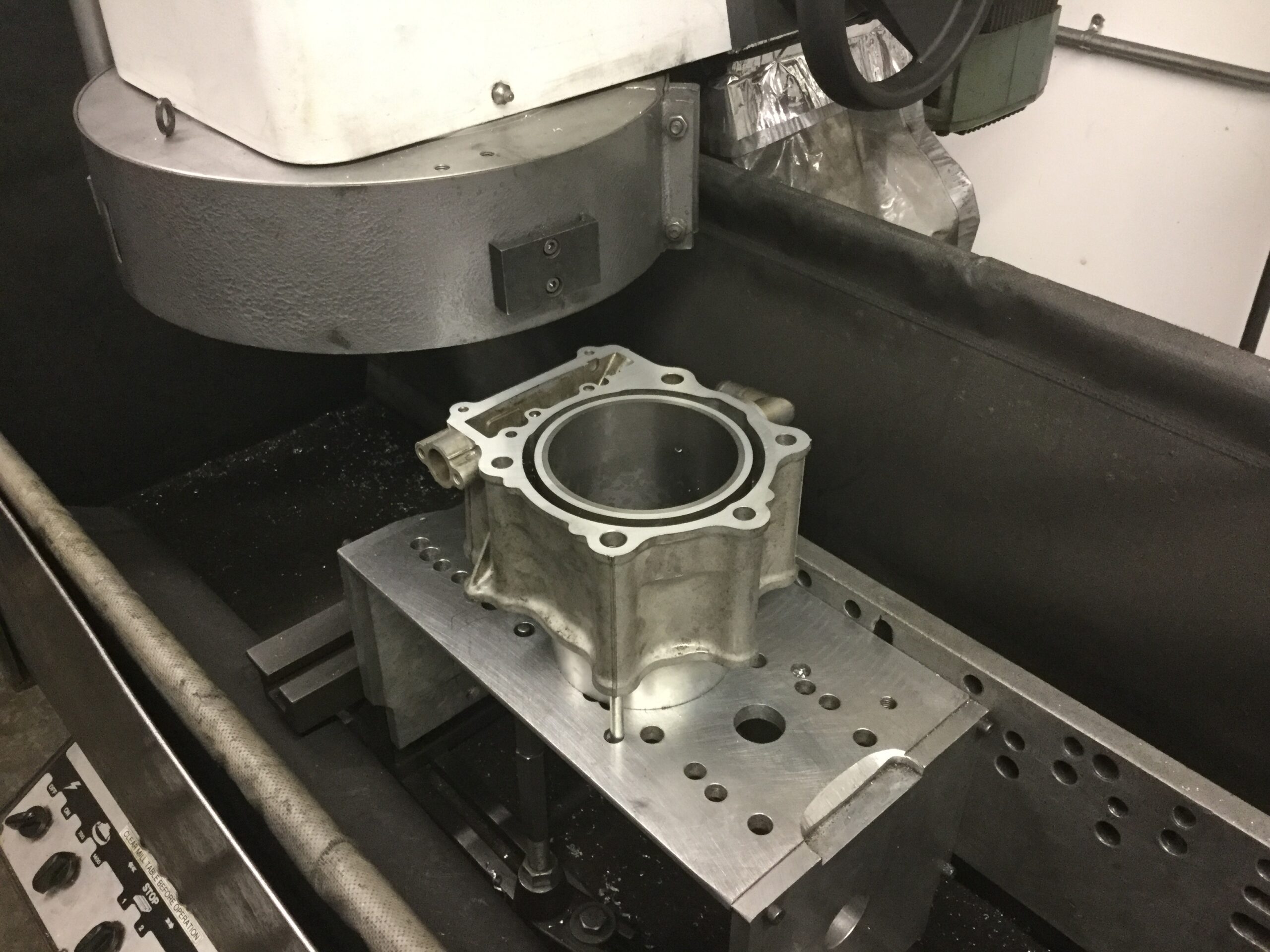

PASS THE ROAST SLEEVES We do quite a few small single cylinder engine, re-bore and power hone jobs in our shop. Usually going to the next available oversize is all that is needed. However, when cylinders are badly damaged or have already been re-bored to the limit, we...