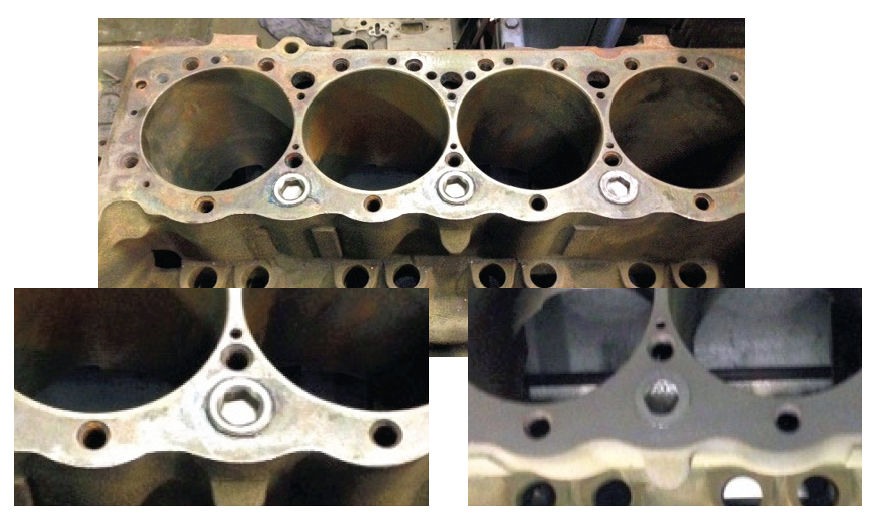

ALIGN HONE ADJUSTMENT At times I have had a main journal that just honed faster than the rest. I cut some .001 shim stock and place it between the stone and journal and give it a few short strokes. The shim stock will stop the honing of that one journal and let the...