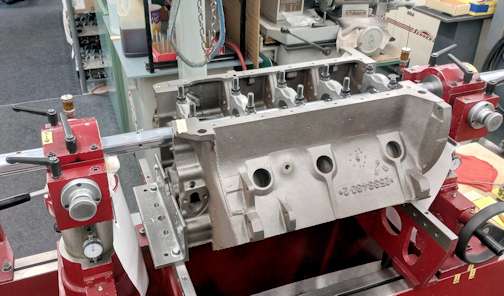

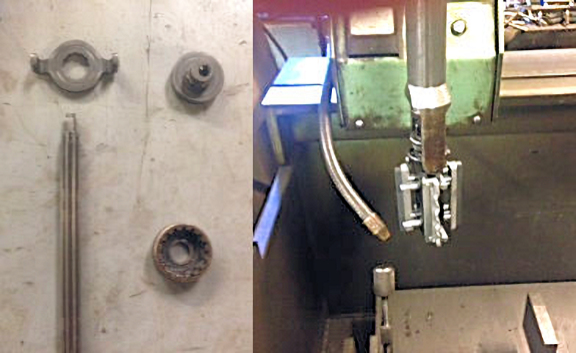

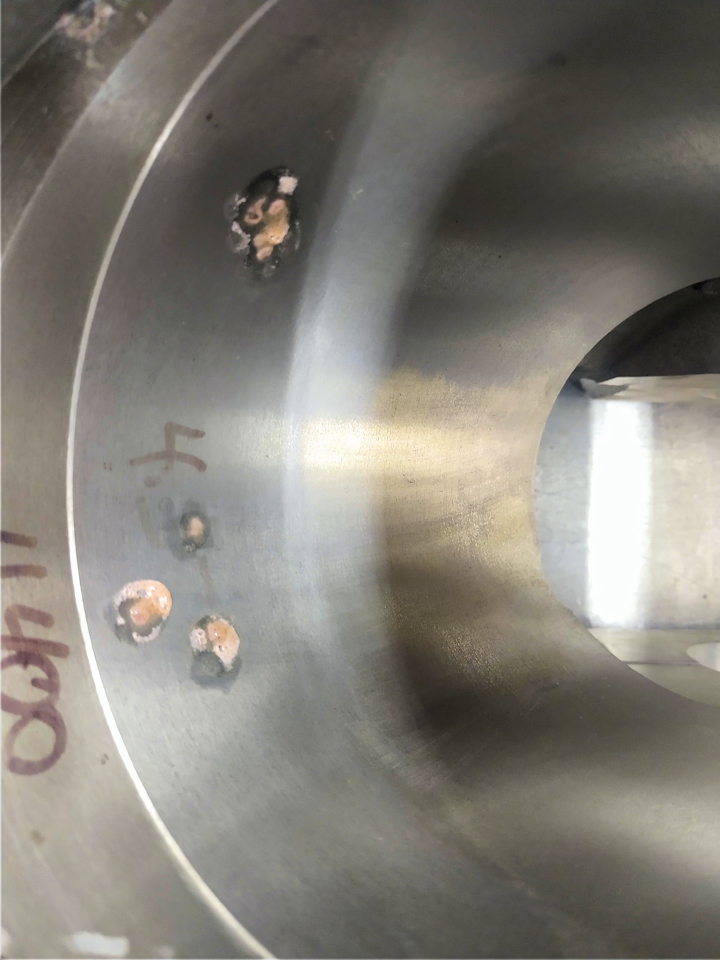

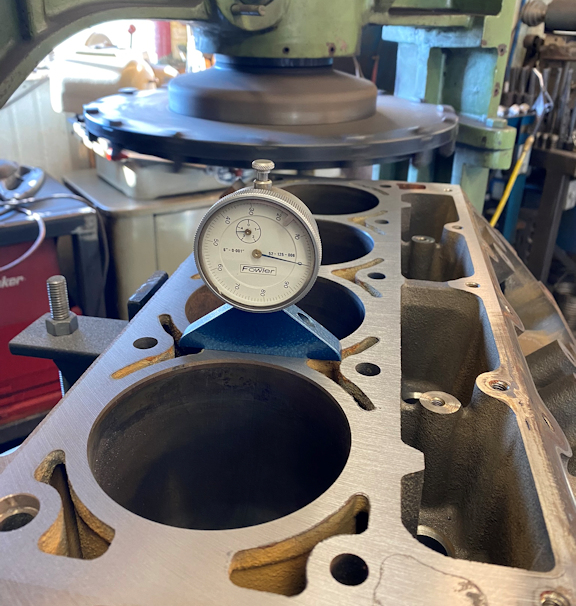

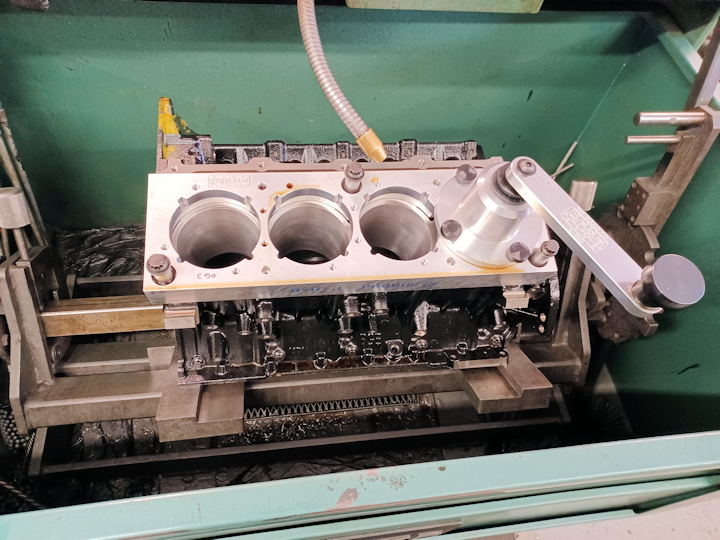

GET IT RIGHT When line boring and trying to figure out bearing clearance on an engine family that's out of your norm, check your clearances before you start. Torque a bearing into a good bore and use the stock fasteners if you plan on aftermarket bolts or studs, so it...