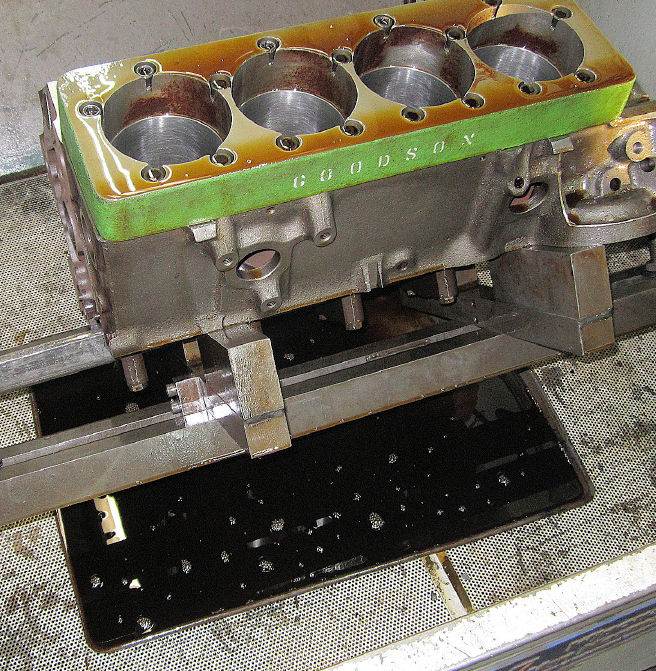

SUBARU CASE CLAMP The Subaru opposed 4-cylinder has a split case or block. I came up with this solution to hold down Subaru blocks so we can surface them. It works real well and holds the block firmly in place. Its a metal bar cut to fit inside of the cylinder. I...