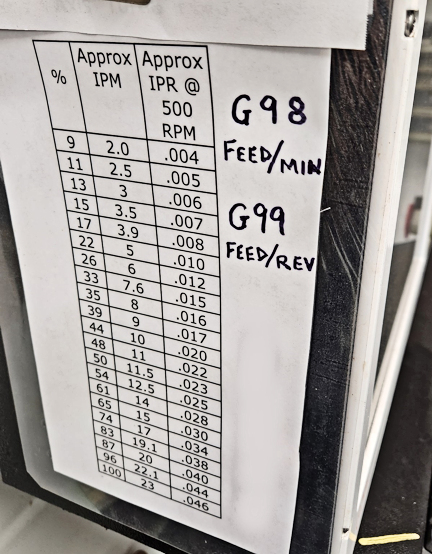

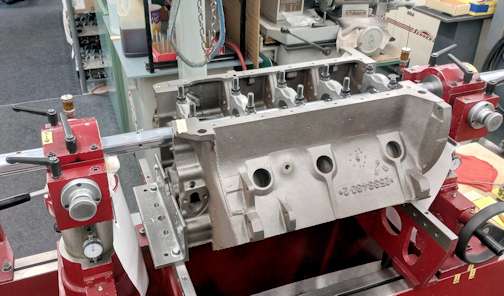

CNC FEED & FEED CHART Shops with CNC mills often need to do a "quick" task, such as drilling a few holes, or taking a cut along one axis, etc. this tip discusses 3 methods to do so. Most machines have a pendant or hand wheels the operator can use to move the tool...