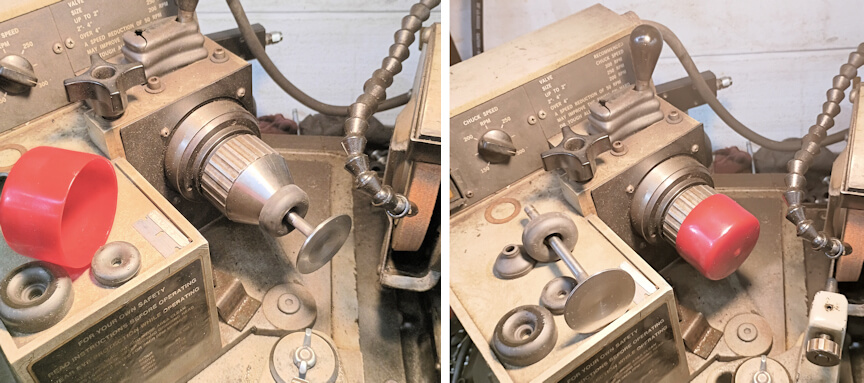

Although it is an old valve facer, it was in tip-top shape when I got it. To keep it that way, I use a rubber cap to cover the chuck when I dress the rock, and those black rubber discs are drum brake wheel cylinder caps. I have two different ones. One is for smaller...