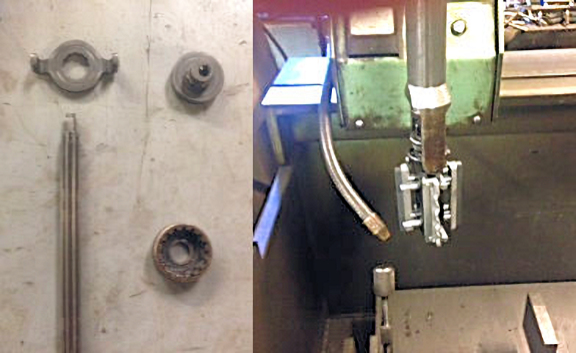

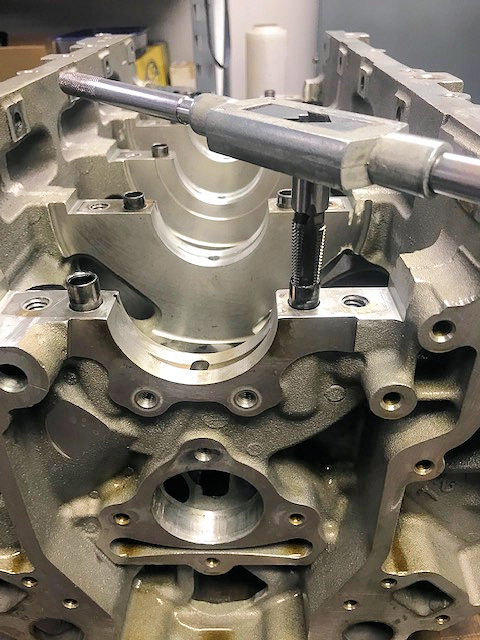

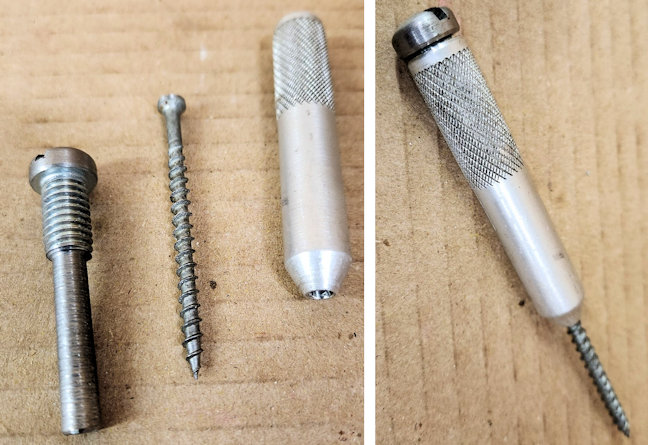

DAMPER/VALVE GUIDE INSTALL TOOL We are a two-man shop, so sometimes wrestling a head this size in the shop press is a bit sketchy. To reduce risk of injury or damage, we installed the guides using our harmonic damper installation tool. It may not be the quickest...