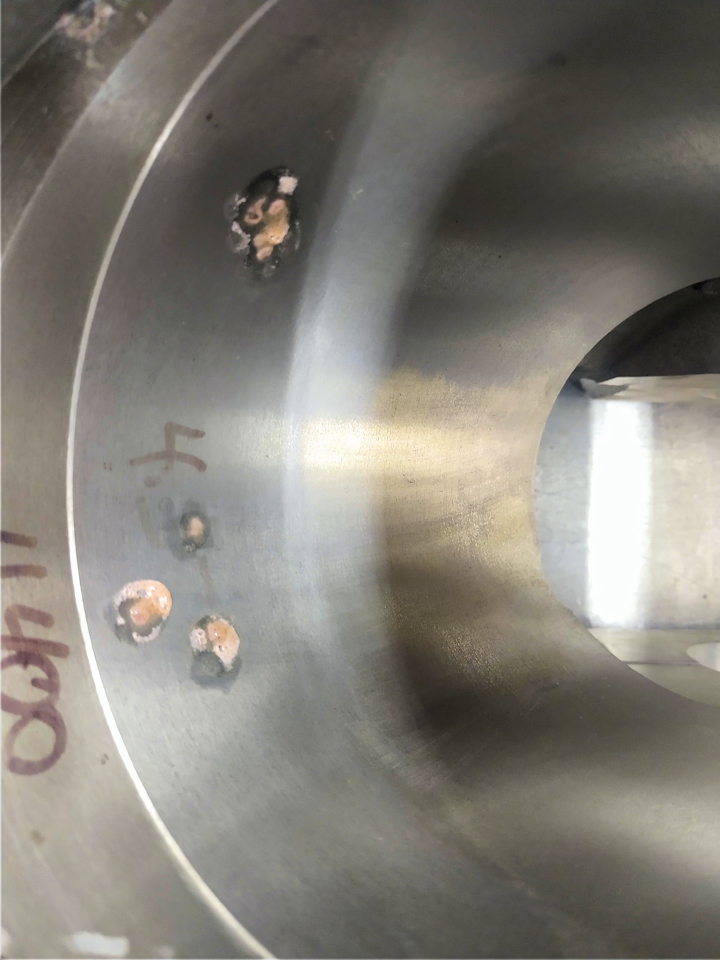

JUST IN CASE YOU MISS Everyone misses occasionally, and this helps avoid dents and damage. When I need to adjust the guides to the correct depth after getting close with the air hammer it's good to protect the head. Everyone misses sooner or later, and this simple...