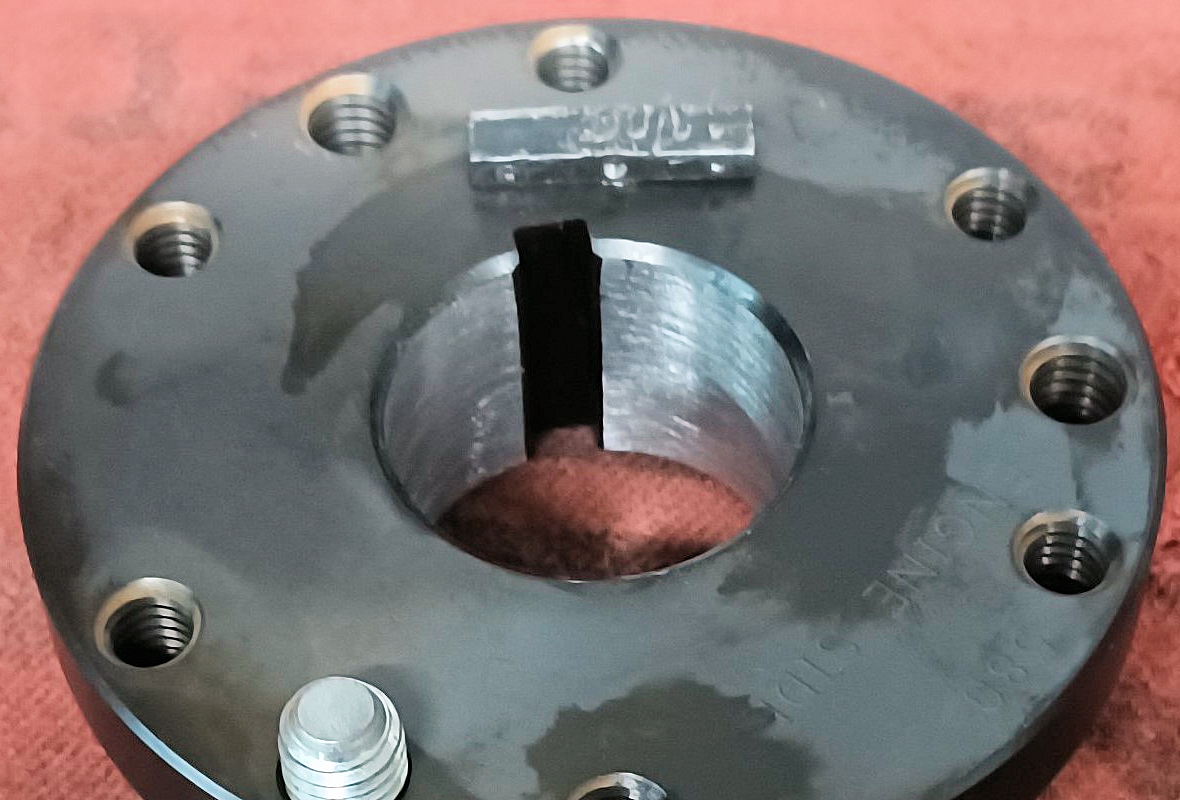

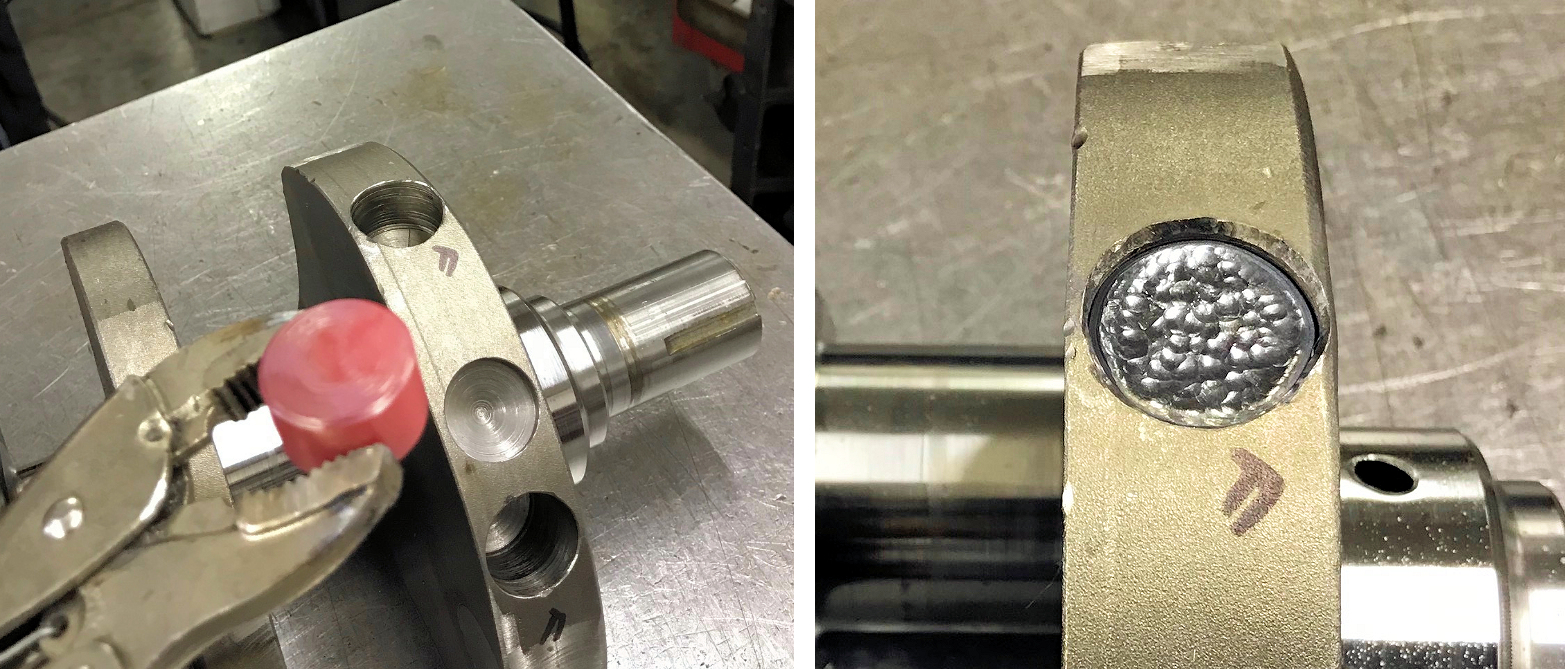

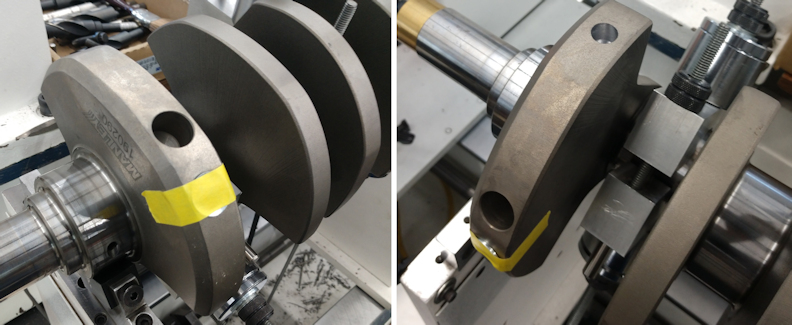

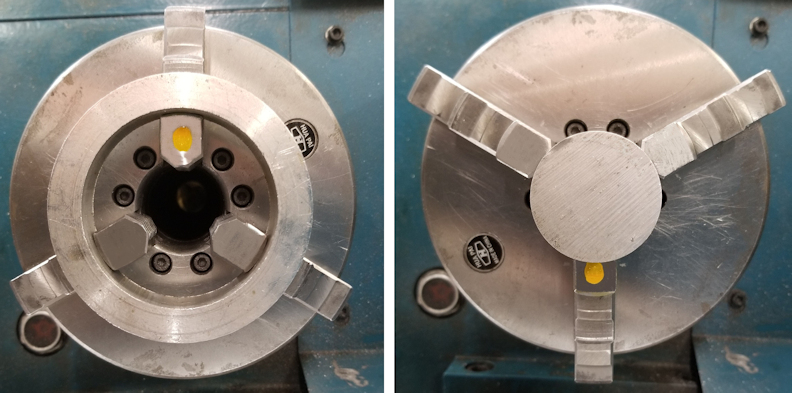

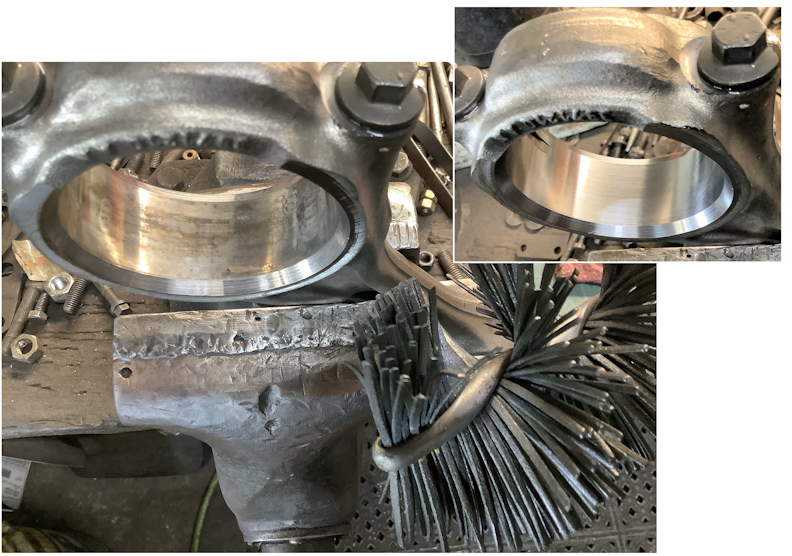

STICKY SITUATION This trick got me through a job that I didn't have the correct tooling for. I don't have a keyway rod hone mandrel in 1.375" so I cut a piece of 1/4" key stock in half to keep the shoes and stone on my mandrel from catching and sticking in the keyway...